Hallenstrahler revolutionieren die Lagerbeleuchtung. Mit einer Hallenstrahlerleuchte wie der dimmbaren Hallenstrahlerleuchte von Rackorapro profitieren Sie sofort von Energieeinsparungen, erhöhter Arbeitssicherheit und gesteigerter Produktivität. Viele Betriebe berichten, dass der Energieverbrauch durch den Umstieg auf Hallenstrahler um bis zu 70 % gesenkt werden kann.

- Hochregalleuchten mit intelligenter Steuerung ermöglichen es Ihnen, die Kosten weiter zu senken, indem die Helligkeit in leeren Räumen angepasst wird.

- Sie können im Vergleich zu herkömmlicher Beleuchtung über 50 % Energie einsparen.

Moderne Lagerhallen benötigen eine fortschrittliche Beleuchtung, um den betrieblichen Anforderungen gerecht zu werden. Die Umrüstung auf eine Hallenbeleuchtung trägt dazu bei, ein helleres, sichereres und effizienteres Arbeitsumfeld zu schaffen.

Wichtigste Erkenntnisse

- Hochregalleuchten können den Energieverbrauch um bis zu 70 % reduzieren, was zu erheblichen Kosteneinsparungen führt.

- Eine verbesserte Beleuchtung erhöht die Sicherheit am Arbeitsplatz und verringert das Risiko von Unfällen und Fehlern.

- LED-Hallenstrahler haben eine Lebensdauer von über 50.000 Stunden, wodurch Wartungs- und Austauschkosten minimiert werden.

- Intelligente Steuerungssysteme ermöglichen Energieeinsparungen durch Anpassung der Helligkeit in ungenutzten Bereichen.

- Hochregalleuchten sorgen für eine gleichmäßige Ausleuchtung und verbessern so die Sichtverhältnisse und die betriebliche Effizienz.

- Die Umrüstung auf Hallenstrahler unterstützt die Nachhaltigkeitsziele durch die Reduzierung der Kohlenstoffemissionen.

- Die Wahl von Leuchten mit Umweltzertifizierungen gewährleistet Sicherheit und die Einhaltung von Vorschriften.

- Eine umfassende Garantie unterstreicht die Zuverlässigkeit der Hallenstrahler und schützt Ihre Investition.

Herausforderungen bei der Lagerbeleuchtung

Unzureichende Beleuchtung

Veraltete Lagerbeleuchtung stellt Sie vor zahlreiche Herausforderungen. Unzureichende Beleuchtung zählt zu den häufigsten Problemen in Lagerhallen. Schlechtes Licht verlangsamt Arbeitsabläufe und erhöht das Fehlerrisiko. Mitarbeiter lesen möglicherweise Produktetiketten falsch oder finden Artikel nur schwer. Schwaches Licht kann zudem Müdigkeit verursachen und so Produktivität und Motivation mindern. Bei schlechter Sicht steigt die Unfallgefahr, da Mitarbeiter Hindernisse oder die Position von Transportgeräten falsch einschätzen.

Tipp: Die richtige Beleuchtung verbessert die Sicht, reduziert Fehler und hilft Ihrem Team, schneller und sicherer zu arbeiten.

Hier einige Beispiele, wie sich unzureichende Beleuchtung auf Ihr Lager auswirkt:

- Erhöhte Fehlerwahrscheinlichkeit bei den Mitarbeitern

- Höhere Unfallwahrscheinlichkeit aufgrund von Fehleinschätzungen der Position und Geschwindigkeit von Objekten

- Verringerte betriebliche Effizienz und langsamere Arbeitsprozesse

- Höheres Risiko von Verletzungen und Entschädigungsansprüchen

- Psychologische Auswirkungen wie Müdigkeit und verminderte Motivation

Hoher Energieverbrauch

Viele Lagerhallen nutzen immer noch herkömmliche Beleuchtungssysteme, die viel Energie verbrauchen. Veraltete Glühbirnen und Leuchten treiben die Energiekosten in die Höhe und belasten Ihre Rentabilität. Sie werden feststellen, dass Ihre monatlichen Rechnungen stetig steigen, insbesondere wenn Ihre Lagerhalle rund um die Uhr in Betrieb ist. Ineffiziente Beleuchtung trägt außerdem zu höheren CO₂-Emissionen bei und erschwert es Ihrem Unternehmen, seine Nachhaltigkeitsziele zu erreichen.

Zu den häufigsten Energieherausforderungen bei der Lagerbeleuchtung gehören:

- Hohe Energiekosten durch ineffiziente Glühbirnen

- Zunehmender Abfall und Umweltbelastung

- Uneinheitliche Lichtqualität, die mehr Leuchten erfordert, um eine ausreichende Helligkeit zu erreichen

Die Umstellung auf moderne Lagerbeleuchtung kann Ihnen helfen, Kosten zu senken und Ihren ökologischen Fußabdruck zu verringern.

Wartungsprobleme

Die Wartung kann Ihren Betriebsablauf stören und Ihre Kosten erhöhen. Herkömmliche Beleuchtungssysteme wie HID- und Leuchtstofflampen haben eine kürzere Lebensdauer und müssen häufig ausgetauscht werden. Jedes Mal, wenn eine Lampe ausfällt, müssen Reparaturen eingeplant werden, was den Arbeitsablauf unterbricht und die Personalkosten erhöht. Zudem können technische Probleme wie Flackern oder ungleichmäßige Ausleuchtung auftreten, die Ihr Team frustrieren und die Arbeitsmoral beeinträchtigen können.

Beachten Sie diese Herausforderungen bei der Instandhaltung:

- Häufiger Lampenwechsel aufgrund kürzerer Lebensdauer

- Höhere Lohn- und Materialkosten für laufende Reparaturen

- Zunehmende Betriebsstörungen durch Beleuchtungsausfälle

LED-Hallenstrahler bieten eine Lösung mit einer Lebensdauer von 50.000 Stunden oder mehr und reduzieren so den Bedarf an Austausch und Wartung erheblich. Die Modernisierung Ihrer Lagerbeleuchtung spart Ihnen Zeit und Geld und sorgt für einen reibungslosen Betrieb Ihrer Anlage.

Sicherheitsbedenken

Wenn Ihre Lagerbeleuchtung nicht den modernen Standards entspricht, sind Sie ernsthaften Sicherheitsrisiken ausgesetzt. Schlechte Beleuchtung kann gefährliche Bedingungen für alle Mitarbeiter in Ihrem Betrieb schaffen. Arbeiter haben möglicherweise Schwierigkeiten, Hindernisse, bewegliche Geräte oder verschüttete Flüssigkeiten auf dem Boden zu erkennen. Diese Sichtprobleme führen häufig zu Unfällen und Verletzungen.

Sie müssen berücksichtigen, wie sich die Beleuchtung auf alle Aspekte der Lagersicherheit auswirkt. Unzureichende Beleuchtung kann zu Ausrutschen, Stolpern und Stürzen führen. Gabelstaplerfahrer können Entfernungen falsch einschätzen oder andere Mitarbeiter übersehen. Notausgänge und Sicherheitskennzeichnungen können schwer erkennbar sein. Wenn Sie diese Risiken ignorieren, erhöhen Sie die Wahrscheinlichkeit von Arbeitsunfällen.

Tipp: Helle, gleichmäßige Beleuchtung hilft, Unfälle zu reduzieren und Ihr Team zu schützen.

Sie müssen auch die Einhaltung der Vorschriften berücksichtigen. Viele Sicherheitsbestimmungen schreiben bestimmte Beleuchtungsstärken in Arbeitsbereichen vor. Entspricht Ihr Lager diesen Standards nicht, riskieren Sie Bußgelder und rechtliche Schritte. Versicherungen können Ihre Prämien erhöhen, wenn sie ein Muster von Unfällen aufgrund mangelhafter Beleuchtung feststellen.

Hier einige häufige Sicherheitsrisiken, die durch unzureichende Beleuchtung verursacht werden:

- Arbeiter erkennen Gefahren wie verschüttete Flüssigkeiten, Trümmer oder unebene Oberflächen möglicherweise nicht.

- Maschinenbediener könnten Schwierigkeiten haben, sich in den Gängen oder Ladezonen zurechtzufinden.

- Notfallmaßnahmen können fehlschlagen, wenn Ausgänge und Alarme nicht deutlich sichtbar sind.

- Die Sicherheitsrisiken steigen, wenn dunkle Bereiche unbefugten Zutritt oder Diebstahl ermöglichen.

In der folgenden Tabelle können Sie sehen, wie sich die Beleuchtung auf die Sicherheit in wichtigen Lagerbereichen auswirkt:

|

Bereich |

Sicherheitsrisiko bei unzureichender Beleuchtung |

Vorteil einer ausreichenden Beleuchtung |

|---|---|---|

|

Laderampen |

Stürze, Zusammenstöße |

Klare Sicht, sicherere Bewegung |

|

Lagergänge |

Stolpern, Verlegenheit |

Einfache Navigation, weniger Unfälle |

|

Notausgänge |

Blockierte Fluchtwege |

Schnelle Evakuierung, Einhaltung der Vorschriften |

|

Sicherheitszonen |

Diebstahl, unbefugter Zugriff |

Abschreckung, bessere Überwachung |

Um ein sichereres Arbeitsumfeld zu schaffen, sollten Sie die Modernisierung Ihrer Beleuchtung priorisieren. Hallenstrahler bieten eine helle und gleichmäßige Ausleuchtung, die Ihnen hilft, Gefahren frühzeitig zu erkennen. Mit einer besseren Beleuchtung schützen Sie Ihre Mitarbeiter und Ihr Unternehmen.

Sie steigern außerdem die Arbeitsmoral. Mitarbeiter fühlen sich in gut beleuchteten Bereichen sicherer und selbstbewusster. Die Produktivität steigt, wenn Ihr Team weiß, dass Ihnen seine Sicherheit am Herzen liegt. Sie leben eine starke Sicherheitskultur in Ihrem Lager vor.

Lösung von Beleuchtungsproblemen in Lagerhallen

Hochregal-Beleuchtungslösungen

Verbesserte Distribution

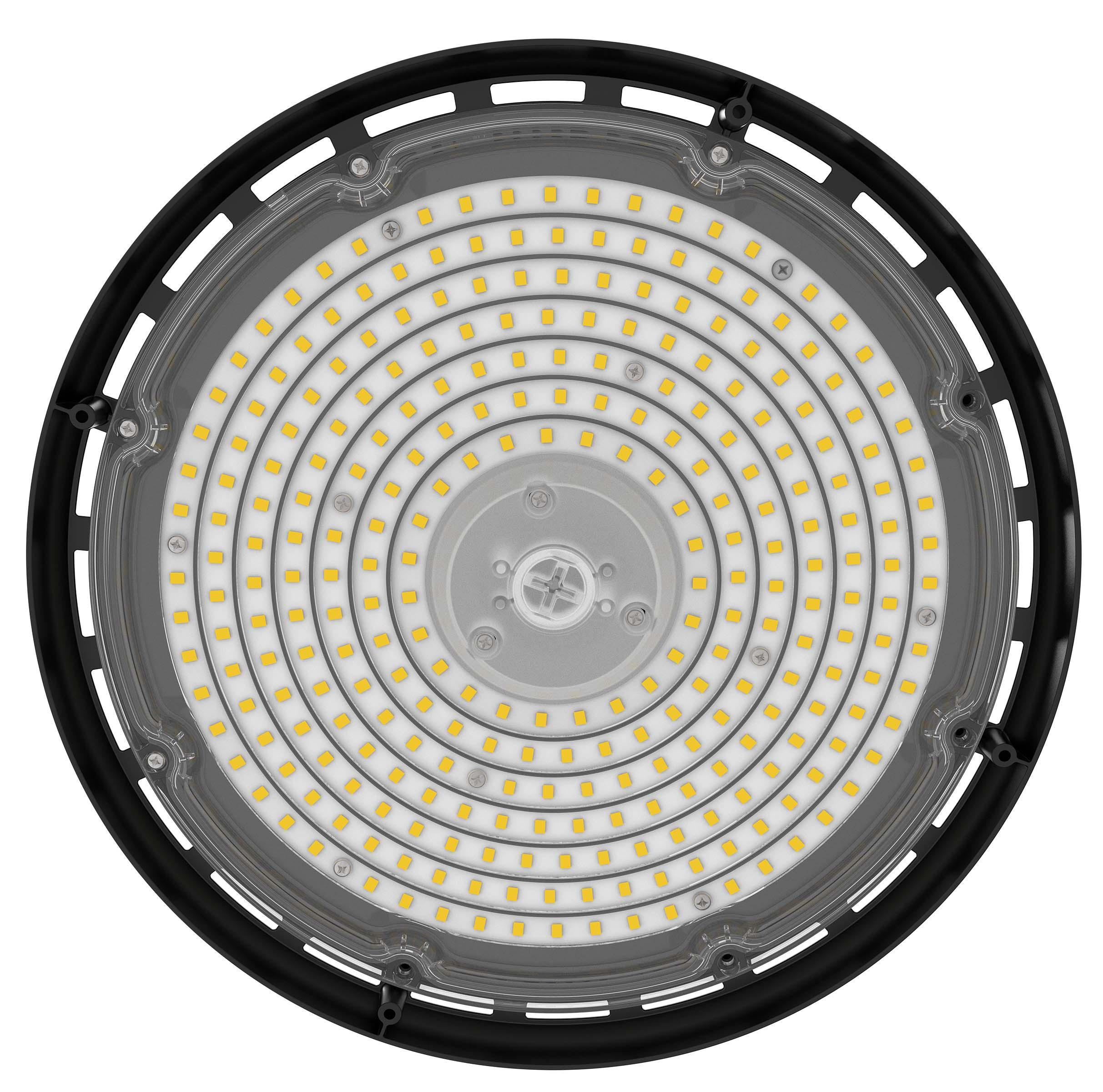

Sie benötigen eine gleichmäßige und leistungsstarke Beleuchtung, um jeden Winkel Ihres Lagers auszuleuchten. Hallenstrahler, wie der dimmbare Hallenstrahler von Rackorapro, liefern mit bis zu 36.000 Lumen eine außergewöhnliche Helligkeit. Diese hohe Lichtleistung sorgt für eine gleichmäßige Ausleuchtung von Gängen, Regalen und Arbeitsplätzen. Schatten und dunkle Ecken werden reduziert, wodurch sich Ihr Team leichter orientieren und effizienter arbeiten kann. Die optimierte Lichtverteilung bedeutet, dass Sie sich weniger Gedanken um die Sichtbarkeit machen müssen und sich stattdessen auf die Produktivität konzentrieren können.

Energieeinsparungen

Durch den Umstieg auf LED-Hallenstrahler können Sie Ihre Energiekosten drastisch senken. Diese Leuchten nutzen fortschrittliche LED-Technologie und verbrauchen deutlich weniger Strom als herkömmliche Lagerhallenbeleuchtung. Dank der wählbaren Wattzahl von Rackorapro können Sie die optimale Leistung für Ihre Räumlichkeiten auswählen und so Energieverschwendung vermeiden. Der hohe Leistungsfaktor und das effiziente Treiberdesign reduzieren den Stromverbrauch zusätzlich. Das Ergebnis: niedrigere Stromrechnungen und ein kleinerer CO₂-Fußabdruck.

Tipp: Geringerer Energieverbrauch bedeutet mehr Geld für andere Verbesserungen in Ihrer Einrichtung.

Verbesserte Sicherheit

Helle und zuverlässige Beleuchtung trägt zu einem sichereren Arbeitsplatz bei. Hallenstrahler verbessern die Sichtverhältnisse und reduzieren so das Unfall- und Verletzungsrisiko. Mitarbeiter können Gefahren schnell erkennen, und Maschinenbediener können sicherer navigieren. Die Feuchtraumtauglichkeit der Rackorapro-Leuchten gewährleistet deren einwandfreie Funktion auch in feuchten Bereichen wie Laderampen oder Kühlhäusern. Mit zuverlässiger Beleuchtung schützen Sie Ihre Mitarbeiter und erfüllen alle Sicherheitsvorschriften.

|

Besonderheit |

Nutzen |

|---|---|

|

Energieeffizienz |

Verbraucht weniger Strom als herkömmliche Leuchten, was zu Energieeinsparungen führt. |

|

Langlebigkeit |

Hält über 50.000 Stunden, wodurch die Wartungskosten gesenkt werden. |

|

Verbesserte Lichtqualität |

Verbessert die Sicht und Sicherheit, reduziert die Augenbelastung und steigert die Produktivität. |

Erweiterte Funktionen

Intelligente Steuerung

Mit intelligenten Funktionen steuern Sie Ihre Lagerbeleuchtung. Bewegungs- und Präsenzsensoren dimmen oder schalten die Beleuchtung in leeren Bereichen automatisch ab und sparen so Energie. Die Tageslichtnutzung passt die künstliche Beleuchtung automatisch an das verfügbare Tageslicht an, insbesondere in der Nähe von Oberlichtern. Dank der Zeitplanfunktion legen Sie Helligkeitsprofile für verschiedene Schichten fest und haben so immer die optimale Lichtmenge. Vernetzte Leuchten liefern Statusaktualisierungen und Diagnosedaten in Echtzeit und helfen Ihnen, Probleme zu erkennen, bevor sie den Betrieb beeinträchtigen. Die Integration in Gebäudemanagementsysteme sorgt dafür, dass Ihre Beleuchtung mit Produktionsplänen und Sicherheitswarnungen synchronisiert ist.

Einstellbare Farbtemperatur

Die dimmbare Hallenleuchte von Rackorapro bietet einstellbare Farbtemperatur und wählbare Wattzahl. Helligkeit und Lichtfarbe lassen sich individuell an die jeweilige Aufgabe anpassen. Für detaillierte Inspektionen wählen Sie ein kühleres Weiß, für allgemeine Arbeiten einen wärmeren Ton. Dank dieser Flexibilität schaffen Sie für jede Aktivität in Ihrem Lager die optimale Umgebung. Die universelle Spannungskompatibilität ermöglicht eine einfache Installation, unabhängig von Ihrem Stromnetz. Mit einer Lebensdauer von über 50.000 Stunden sparen Sie Zeit bei der Wartung und können sich voll und ganz auf Ihr Kerngeschäft konzentrieren.

Hinweis: Erweiterte Funktionen wie einstellbare Farbtemperatur und intelligente Steuerungsmöglichkeiten helfen Ihnen, die Beleuchtung für jeden Lagerbetrieb zu optimieren.

Vorteile von Hallenstrahlern

Energieeffizienz

Sie möchten Ihre Lagerbetriebskosten senken? Hallenstrahler helfen Ihnen dabei dank ihrer hohen Energieeffizienz. Mit LED-Hallenstrahlern verbrauchen Sie weniger Strom als mit herkömmlichen Leuchten. Das bedeutet eine direkte Reduzierung Ihrer monatlichen Energiekosten. Die dimmbare Hallenstrahler von Rackorapro bieten eine wählbare Wattzahl und einen hohen Leistungsfaktor, sodass Sie die Lichtleistung optimal an Ihre Bedürfnisse anpassen und dabei Strom sparen können.

Hier ein Vergleich der wichtigsten Merkmale, die die Energieeffizienz bei der Lagerbeleuchtung beeinflussen:

|

Besonderheit |

Nutzen |

|---|---|

|

Energieverbrauch |

LED-Hallenstrahler verbrauchen weniger Strom als herkömmliche Beleuchtungsmittel, wodurch die Kosten gesenkt werden. |

|

Lebensdauer |

Eine längere Lebensdauer bedeutet weniger Austausch und somit geringere Wartungskosten. |

|

Bewegungssensoren |

Die Helligkeit wird automatisch an die Aktivität angepasst, um Energieverschwendung zu minimieren. |

|

Umweltfreundlich |

LEDs sind quecksilberfrei, wodurch sie sicherer zu entsorgen und nachhaltiger sind. |

Man sieht also, dass Hallenstrahler nicht nur Energie sparen, sondern auch zu einem nachhaltigeren Lager beitragen. Dadurch sind sie eine umweltfreundliche Beleuchtungsoption für moderne Lagerhallen.

Helligkeit und Abdeckung

Für ein sicheres und produktives Lager benötigen Sie eine helle und gleichmäßige Beleuchtung. Hallenstrahler liefern eine hohe Lichtleistung (Lumen), wodurch Sie mehr Licht bei geringerem Energieverbrauch erhalten. Der dimmbare Hallenstrahler von Rackorapro erzeugt bis zu 36.000 Lumen, sodass Sie große Flächen mit weniger Leuchten ausleuchten können. Dies reduziert Schatten und dunkle Bereiche und verbessert die Sicht und Bewegungssicherheit Ihrer Mitarbeiter.

Vergleichen Sie die Leistung von Hallenstrahlern und herkömmlichen Leuchten:

|

Beleuchtungsart |

Lichtstrom |

Energieeffizienz |

|---|---|---|

|

LED-Hallenstrahler |

Hohe Lichtausbeute |

Bis zu 75 % weniger Energieverbrauch |

|

Traditionelle Einrichtungsgegenstände |

Geringere Lichtausbeute |

Höherer Energieverbrauch |

Mit Hallenstrahlern erzielen Sie eine bessere Ausleuchtung und Sichtbarkeit in Ihrem gesamten Lager. Dies beschleunigt die Arbeitsabläufe und reduziert das Unfallrisiko. Zudem verbessern Sie die allgemeine Beleuchtungsqualität Ihres Lagers, was die Mitarbeitermotivation und Produktivität steigert.

Haltbarkeit

Sie wünschen sich langlebige und wartungsarme Beleuchtung? Hallenstrahler zeichnen sich durch ihre Robustheit aus. Der dimmbare Hallenstrahler von Rackorapro ist für über 50.000 Betriebsstunden ausgelegt. Das bedeutet weniger Zeit- und Kostenaufwand für den Lampenwechsel oder die Reparatur von Leuchten. Dank seiner robusten Bauweise ist er feuchtigkeits- und temperaturbeständig und somit in jeder Lagerhalle zuverlässig einsetzbar.

Werfen Sie einen Blick darauf, wie die durchschnittliche Lebenserwartung im Vergleich aussieht:

|

Beleuchtungsart |

Durchschnittliche Lebensdauer |

|---|---|

|

Hochregalleuchten (LED) |

Bis zu 100.000 Stunden |

|

Traditionelle Beleuchtung |

10.000 - 15.000 Stunden |

Die Umstellung auf LED-Hallenstrahler reduziert die Wartungskosten auf verschiedene Weise:

- Man muss die Glühbirnen seltener austauschen, was die Arbeitskosten senkt.

- Das Risiko einer Überhitzung sinkt, wodurch Schäden und Ausfälle vermieden werden.

- Sie sparen mit der Zeit Geld bei Reparaturen und Ersatzbeschaffungen.

Langlebige Beleuchtung sorgt für einen reibungslosen Lagerbetrieb. Sie vermeiden ungeplante Ausfallzeiten und können sich auf Ihr Kerngeschäft konzentrieren.

Umweltfreundliches Design

Sie möchten, dass Ihre Lagerbeleuchtung Ihre Nachhaltigkeitsziele unterstützt. Hallenstrahler, insbesondere moderne Modelle wie der dimmbare Hallenstrahler von Rackorapro, helfen Ihnen, Ihre Umweltbelastung zu reduzieren. Diese LED-Leuchten verbrauchen weniger Energie, wodurch Sie Ihren CO₂-Fußabdruck täglich verringern. Außerdem vermeiden Sie Schadstoffe, die in älteren Beleuchtungstechnologien enthalten sind.

Viele Hallenstrahler erfüllen strenge Umweltzertifizierungen. Diese Standards belegen, dass Ihr Beleuchtungssystem sicher für Mensch und Umwelt ist. Achten Sie auf Zertifizierungen wie UL, Energy Star und DLC. Diese Siegel bestätigen, dass Ihre Leuchten energieeffizient sind und hohe Sicherheitsstandards erfüllen.

Hier ist eine Tabelle mit gängigen Umweltzertifizierungen für Hallenstrahler:

|

Name der Zertifizierung |

Beschreibung |

|---|---|

|

CE-Zertifizierung |

Gewährleistet die Einhaltung der Gesundheits-, Umwelt- und Sicherheitsvorschriften in der EU. |

|

RoHS-Zertifizierung |

Stellt sicher, dass LED-Leuchten durch die Beschränkung bestimmter Materialien gesundheits- und umweltverträglich sind. |

|

Ökodesign-Richtlinie |

Förderung nachhaltiger und energieeffizienter Design- und Herstellungsprozesse für LED-Leuchten. |

|

ErP |

Setzt Leistungsstandards für energieverbrauchende Produkte und fördert so die Nachhaltigkeit. |

|

UL-Zertifizierung |

Gewährleistet Sicherheit vor Stromschlägen und Brandgefahren und legt gleichzeitig Wert auf ökologische Nachhaltigkeit. |

|

Energy Star |

Kennzeichnet Energieeffizienz, was darauf hinweist, dass die Produkte weniger Energie verbrauchen und zum Umweltschutz beitragen. |

|

DLC-Liste |

Der Fokus liegt auf Energieeffizienz und Lichtleistung, wodurch die Lichtverschmutzung reduziert wird. |

Tipp: Die Wahl von Hallenstrahlern mit diesen Zertifizierungen hilft Ihnen, Umweltstandards zu erfüllen und das Nachhaltigkeitsprofil Ihres Lagers zu verbessern.

Sie profitieren außerdem vom umweltfreundlichen Design der Rackorapro-Hallenstrahler. Diese Leuchten enthalten kein Quecksilber oder andere Schadstoffe. Am Ende ihrer Lebensdauer können Sie sie recyceln und so Ihre Umweltinitiativen unterstützen. Dank des effizienten Treibers und des hohen Leistungsfaktors verbrauchen Sie weniger Strom, sparen Geld und schonen die Umwelt.

Garantie & Zuverlässigkeit

Sie brauchen zuverlässige Beleuchtung. Die dimmbare Hallenleuchte von Rackorapro bietet eine 5-jährige eingeschränkte Garantie. Diese Garantie gibt Ihnen Sicherheit und unterstreicht das Vertrauen des Herstellers in die Produktqualität. Ihre Investition ist somit gegen Mängel und Leistungsprobleme geschützt.

LED-Hallenstrahler bieten oft längere Garantien als herkömmliche Lagerbeleuchtung. Eine 5-Jahres-Garantie signalisiert hohe Qualität. Sie vermeiden häufige Reparaturen und Austausch, was Ihre Wartungskosten senkt. Zudem reduzieren Sie Ausfallzeiten in Ihrem Lager, da eine zuverlässige Beleuchtung einen reibungslosen Betriebsablauf gewährleistet.

Beachten Sie diese Vorteile einer umfassenden Garantie:

- Sie sparen Geld bei Reparaturen und Ersatzbeschaffungen.

- Sie minimieren Störungen Ihres Arbeitsablaufs.

- Sie gewinnen Vertrauen in die langfristige Leistungsfähigkeit Ihres Beleuchtungssystems.

Hinweis: Eine mehrjährige Garantie unterstreicht die Langlebigkeit und Zuverlässigkeit Ihrer Beleuchtungslösung. Sie können sich auf Ihr Kerngeschäft konzentrieren, denn Ihr Lager bleibt stets optimal beleuchtet und effizient.

Rackorapros Engagement für Zuverlässigkeit garantiert Ihnen jahrelang gleichbleibende Leistung. Die lange Lebensdauer und die robuste Bauweise gewährleisten, dass Ihre Leuchten auch anspruchsvollen Lagerbedingungen standhalten. Mit Hallenstrahlern und umfassender Garantie treffen Sie eine kluge Investition.

Anwendungen in der Lagerbeleuchtung

Speicheroptimierung

Mit Hallenstrahlern optimieren Sie Ihre Lagerkapazität . Diese Leuchten sorgen für eine leistungsstarke Ausleuchtung aller Regalböden, selbst in Lagern mit hohen Regalsystemen. Durch die Installation von Hallenstrahlern verbessern Sie die Sichtbarkeit von Warenregalen, Geräteauslagen und Sicherheitskennzeichnungen. Ihre Mitarbeiter finden Artikel schneller und vermeiden Fehler beim Kommissionieren und Einlagern.

|

Aspekt |

Beschreibung |

|---|---|

|

Sichtweite |

Verbessert die Sichtbarkeit von bestückten Regalen, Geräteauslagen und Sicherheitsbeschilderungen. |

|

Betriebliche Effizienz |

Verbessert die betriebliche Effizienz und verringert das Unfallrisiko durch ausreichende Beleuchtung der Arbeitsabläufe. |

|

Gefahrenvermeidung |

Unzureichende vertikale Beleuchtung kann gefährliche Bedingungen für den Betrieb von Gabelstaplern schaffen. |

Energieeffiziente Beleuchtung senkt Ihre Betriebskosten. Dank der langen Lebensdauer von LED-Leuchten sparen Sie Zeit und Geld bei der Wartung. Die optimale Anordnung von Hallenstrahlern verhindert Überbeleuchtung und Energieverschwendung. So schaffen Sie ein gut organisiertes Lager, in dem jeder Artikel leicht zu finden und jeder Gang sicher begehbar ist.

Tipp: Helle, gleichmäßige Beleuchtung hilft Ihnen, die Lagerung zu optimieren und die Bestandsverwaltung zu vereinfachen.

Arbeitssicherheit

Mit der Umrüstung auf LED-Hallenbeleuchtung schützen Sie Ihr Team. Diese Leuchten verbessern die Sichtverhältnisse in Ihrem gesamten Lager und reduzieren so Unfälle wie Stolpern und Stürzen. Mitarbeiter bewegen sich sicher in gut beleuchteten Gängen und Ladezonen. Schlechte Beleuchtung trägt zu Stürzen am Arbeitsplatz bei, die Unternehmen jährlich Milliarden von Dollar kosten. Sie können diese Risiken minimieren, indem Sie sicherstellen, dass alle Bereiche den empfohlenen Beleuchtungsstandards entsprechen.

- Hochregallagerbeleuchtung mit LED-Beleuchtung verbessert die Sichtverhältnisse in Lagerhallen und verringert so Unfälle wie Stolpern und Stürzen.

- Die Umrüstung auf Hallenbeleuchtung trägt dazu bei, die OSHA-Beleuchtungsstandards zu erfüllen und somit ein sichereres Arbeitsumfeld zu gewährleisten.

Sie unterstützen damit auch die Einhaltung von Sicherheitsvorschriften. Die OSHA schreibt bestimmte Beleuchtungsstärken in Arbeitsbereichen vor. Hallenstrahler helfen Ihnen, diese Standards zu erfüllen und Bußgelder oder rechtliche Probleme zu vermeiden. Mit einer Investition in bessere Beleuchtung zeigen Sie Ihr Engagement für die Sicherheit Ihrer Mitarbeiter und schaffen ein positives Arbeitsumfeld.

Hinweis: Sicherere Lager führen zu höherer Arbeitsmoral und besserer Produktivität.

Inspektion und Automatisierung

Mit Hallenstrahlern optimieren Sie Qualitätskontrolle und Automatisierung. Diese Leuchten liefern bis zu 30.000 Lumen und eignen sich ideal zur Fehlererkennung an Produkten. Helles und flimmerfreies Licht verbessert die Sichtverhältnisse bei Inspektionsarbeiten. Automatisierte Systeme wie Roboter und Förderbänder benötigen eine gleichmäßige Beleuchtung für einen effizienten Betrieb.

- Gut beleuchtete Umgebungen sind für den Betrieb von Robotersystemen und Förderanlagen unerlässlich und steigern die Produktivität.

- Hochregalleuchten unterstützen Präzision und Effizienz in der Automatisierung.

- Die Integration mit Bewegungssensoren optimiert den Energieverbrauch in Anlagen mit Robotersystemen.

Sie ermöglichen es fortschrittlichen Inspektionssystemen, Fehler schnell zu erkennen. Automatisierte Anlagen arbeiten in Räumen mit zuverlässiger Beleuchtung effizienter. Sie sparen Energie durch intelligente Steuerungen, die das Licht in ungenutzten Bereichen dimmen oder abschalten. Hallenstrahler tragen dazu bei, hohe Qualitäts- und Effizienzstandards in Ihrem Lager zu gewährleisten.

Tipp: Zuverlässige Beleuchtung unterstützt sowohl die manuelle als auch die automatisierte Inspektion und hilft Ihnen so, Ihren Kunden bessere Produkte zu liefern.

Beispiele für Energieeinsparungen

Durch die Umrüstung Ihrer Lagerbeleuchtung auf LED-Hallenstrahler können Sie Ihre Energiekosten drastisch senken. Viele Lagerleiter berichten von beeindruckenden Einsparungen nach dem Umstieg. Hallenstrahler nutzen fortschrittliche LED-Technologie, die weniger Strom verbraucht und mehr Licht liefert. Sie profitieren von niedrigeren Energiekosten und einem nachhaltigeren Betrieb.

Betrachten Sie diese Beispiele aus der Praxis:

- XYZ Logistics, ein mittelständisches Lager in Ohio, ersetzte 200 veraltete HID-Leuchten durch LED-Hallenstrahler. Durch diese Modernisierung sanken die jährlichen Energiekosten von 15.000 auf 4.500 US-Dollar. Die Einsparungen ermöglichten es dem Unternehmen, in weitere Verbesserungen zu investieren und seinen Gewinn zu steigern.

- In einer 50.000 Quadratfuß großen Lagerhalle können Sie durch die Umstellung auf LED-Hallenstrahler jährlich 10.000 US-Dollar oder mehr einsparen. Diese Einsparungen ergeben sich aus dem geringeren Stromverbrauch und dem reduzierten Wartungsaufwand.

- Eine andere Einrichtung erzielte ähnliche Ergebnisse. Nach der Installation von LED-Hallenstrahlern konnten die jährlichen Energiekosten von 15.000 auf 4.500 US-Dollar gesenkt werden. Die Investition von 25.000 US-Dollar amortisierte sich in weniger als zwei Jahren.

Tipp: Anhand dieser Beispiele können Sie Ihr eigenes Einsparpotenzial abschätzen. Berechnen Sie Ihre aktuellen Energiekosten und vergleichen Sie diese mit den voraussichtlichen Kosten durch LED-Hallenbeleuchtung.

Sie profitieren auch langfristig. Hallenstrahler haben eine deutlich längere Lebensdauer als herkömmliche Leuchten. Dadurch reduzieren sich Ihre Ausgaben für Ersatz und Reparaturen. Dank des effizienten Designs verbrauchen Sie weniger Strom für die gleiche Lichtmenge. Mit der Zeit summieren sich diese Einsparungen und helfen Ihnen, Ihre Nachhaltigkeitsziele zu erreichen.

Viele Lagerhallen sind rund um die Uhr in Betrieb. Die Beleuchtung macht einen Großteil der Energiekosten aus. Mit LED-Hallenstrahlern senken Sie Ihre monatlichen Kosten und reduzieren Ihren CO₂-Fußabdruck. Zudem verbessern Sie die Lichtqualität in Ihren Räumlichkeiten, was Sicherheit und Produktivität fördert.

Hier ist eine einfache Tabelle, die Ihnen hilft, die Auswirkungen zu visualisieren:

|

Lagergröße |

Jährliche Energiekosten (alte Beleuchtung) |

Jährliche Energiekosten (LED-Hallenbeleuchtung) |

Jährliche Einsparungen |

|---|---|---|---|

|

Mittelgroß (XYZ Ohio) |

15.000 US-Dollar |

4.500 US-Dollar |

10.500 US-Dollar |

|

50.000 Quadratfuß |

15.000 US-Dollar |

4.500 US-Dollar |

10.500 $ und mehr |

Sie sehen also, dass LED-Hallenstrahler eine intelligente Möglichkeit bieten, Kosten zu senken und Ihre Lagerumgebung zu verbessern. Mit der Investition in moderne Beleuchtung schaffen Sie einen helleren, sichereren und effizienteren Arbeitsbereich.

Auswahl von Hallenstrahlern

Bedarfsanalyse

Bevor Sie die passenden Hallenstrahler auswählen, sollten Sie zunächst die individuellen Anforderungen Ihres Lagers analysieren. Messen Sie dazu Größe und Grundriss Ihrer Lagerhalle aus. Große Lagerhallen benötigen mehr Leuchten und eine strategische Platzierung, um eine optimale Ausleuchtung aller Bereiche zu gewährleisten. Berücksichtigen Sie die Deckenhöhe, da höhere Decken eine höhere Wattzahl und spezifische Abstrahlwinkel für eine effektive Ausleuchtung erfordern. Ermitteln Sie die Art der in den einzelnen Bereichen durchgeführten Arbeiten. Lagerbereiche, Packstationen und Laderampen benötigen möglicherweise unterschiedliche Helligkeitsstufen.

Berücksichtigen Sie bei der Beurteilung Ihres Beleuchtungsbedarfs folgende Schlüsselfaktoren:

- Messen Sie die Abmessungen und die Deckenhöhe des Lagers.

- Ermitteln Sie, welche Aktivitäten in den einzelnen Bereichen den Lichtverhältnissen entsprechen.

- Analysieren Sie das aktuelle Beleuchtungssystem auf Lücken in der Ausleuchtung oder Effizienz.

Achten Sie außerdem auf Helligkeit und Lichtstrom (Lumen), Abstrahlwinkel, Farbtemperatur, Energieeffizienz, Langlebigkeit und die Integration intelligenter Technologien. Diese Faktoren tragen dazu bei, ein sicheres und produktives Arbeitsumfeld in Ihren Lagerhallen zu schaffen.

|

Faktor |

Beschreibung |

|---|---|

|

Deckenhöhe |

Stellen Sie sicher, dass die Beleuchtung den Boden und die Arbeitsbereiche erreicht. |

|

Raumnutzung |

Die Helligkeitsstufen sollten der Art der jeweiligen Tätigkeit in den einzelnen Bereichen angepasst werden. |

|

Energieeffizienz |

Entscheiden Sie sich für LED-Optionen, um Kosten und Wartungsaufwand zu senken. |

|

Helligkeit und Lichtstrom |

Wählen Sie die Leuchten anhand der Lumenleistung für optimale Sichtverhältnisse aus. |

|

Strahlwinkel |

Entscheiden Sie sich zwischen fokussierter oder umfassender Berichterstattung. |

|

Farbtemperatur |

Kühlere Temperaturen verbessern die Sicht und imitieren das Tageslicht. |

|

Installation und Wartung |

Berücksichtigen Sie die einfache Installation und den laufenden Wartungsaufwand. |

|

Zusätzliche Funktionen |

Achten Sie auf Dimmfunktionen und intelligente Steuerungsmöglichkeiten für eine optimale Nutzung. |

Optionen vergleichen

Beim Vergleich von Hallenstrahlern sollten Sie auf Merkmale achten, die Leistung und Wertbeständigkeit beeinflussen. Der dimmbare Hallenstrahler von Rackorapro überzeugt durch wählbare Wattzahlen, einstellbare Farbtemperatur und hohe Lichtausbeute. Sie können zwischen Farbtemperaturen von 3500 K, 4000 K oder 5000 K wählen, um die optimale Beleuchtung für verschiedene Aufgaben in Ihrem Lager zu gewährleisten. Das robuste Metallgehäuse sorgt für Langlebigkeit auch in stark frequentierten Umgebungen. Mit einer Energieeffizienz von bis zu 135 Lumen pro Watt senken Sie Ihre Betriebskosten.

Nutzen Sie diese Tabelle, um wichtige Merkmale zu vergleichen:

|

Besonderheit |

Beschreibung |

|---|---|

|

Lichtstrom |

Bis zu 30.431 Lumen für hervorragende Sichtverhältnisse in großen Räumen |

|

Wählbare Wattzahlen |

Optionen von 110 W bis 220 W für verschiedene Montagehöhen |

|

Einstellbare Farbtemperatur |

3500K, 4000K und 5000K für optimale Aufgabenleistung |

|

Haltbarkeit |

Robuste Gehäuse für stark frequentierte Umgebungen |

|

Energieeffizienz |

Hohe Effizienz zur Senkung der Energiekosten |

|

Zertifizierungen |

DLC Premium- und UL-gelistet für Sicherheit und Konformität |

|

Anwendungen |

Geeignet für Lagerhallen, Fitnessstudios, Produktionsstätten und Einzelhandelsflächen |

Sie profitieren von kostenlosem Versand, einer Zufriedenheitsgarantie und Mengenrabatten, wenn Sie sich für die dimmbare Hallenleuchte von Rackorapro entscheiden. Diese Vorteile erleichtern Ihnen die Modernisierung Ihrer Lagerbeleuchtung ohne zusätzlichen Aufwand.

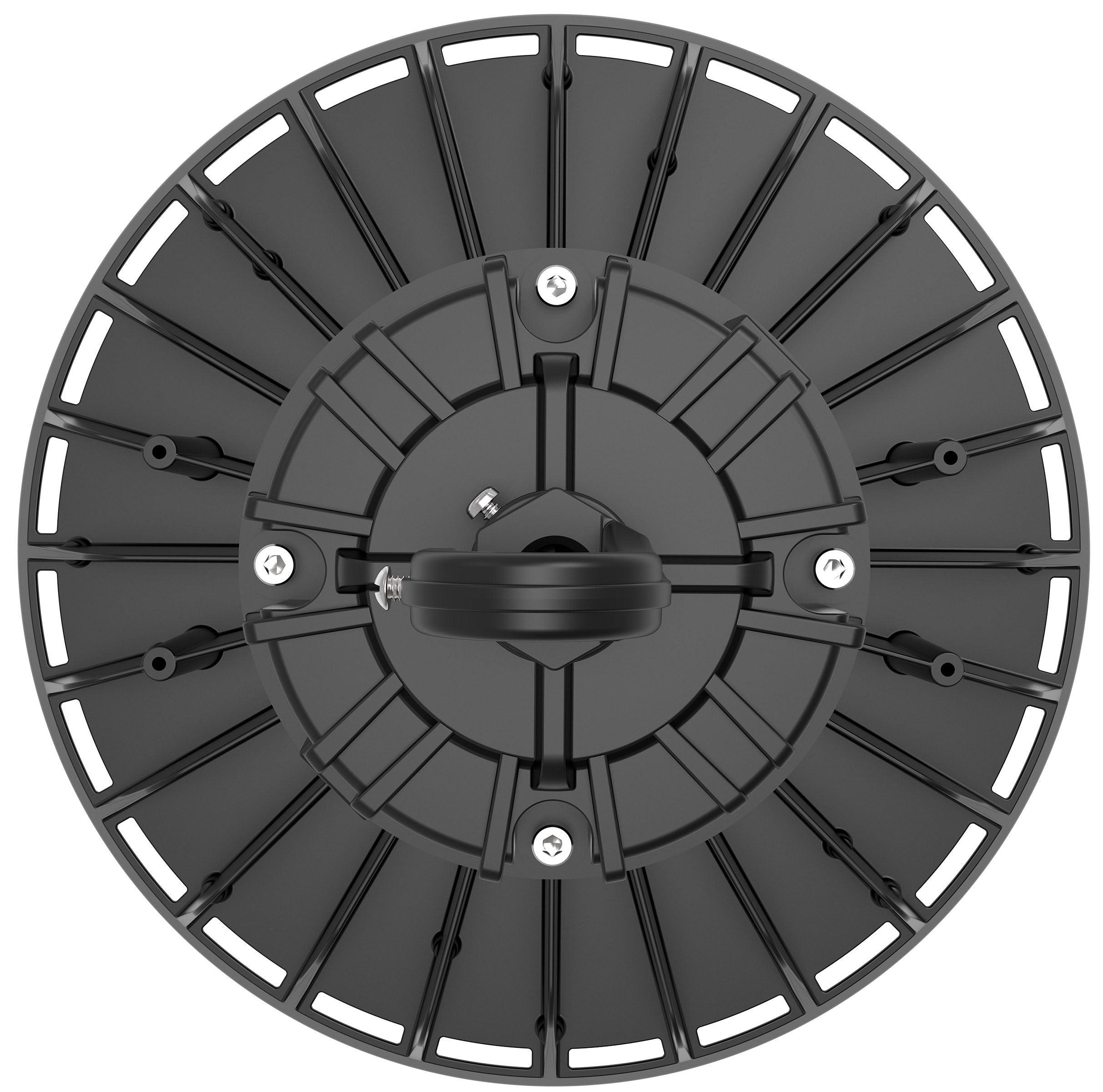

Installationstipps

Eine fachgerechte Installation sorgt für optimale Ergebnisse mit Ihrer Beleuchtungsinvestition. Beginnen Sie mit der Entwicklung eines photometrischen Beleuchtungsplans, um die Leuchten strategisch zu platzieren. Verwenden Sie Farbtemperaturen zwischen 4000 K und 5000 K für eine angenehme und effektive Beleuchtung in Lagerhallen. LED-Hallenstrahler können vorhandene Leuchten direkt ersetzen, wodurch die Installation schnell und unkompliziert verläuft. Die Installation einer Leuchte dauert in der Regel 10–15 Minuten.

Befolgen Sie diese bewährten Vorgehensweisen:

- Stellen Sie sicher, dass die Lichtverhältnisse den empfohlenen Standards für Ihre Lagertätigkeiten entsprechen.

- Nutzen Sie Bewegungssensoren und Lichtsteuerungen, um den Energieverbrauch zu optimieren.

- Installieren Sie Notbeleuchtung für die Sicherheit bei Stromausfällen.

- Die Anlagen sollten regelmäßig gewartet werden, um mögliche Probleme frühzeitig zu erkennen und die Effizienz zu maximieren.

- Bei größeren Projekten empfiehlt sich eine professionelle Installation.

Mit diesen Tipps schaffen Sie ein sichereres, helleres und effizienteres Lager. Die Modernisierung Ihrer Beleuchtungsanlage steigert die Produktivität und senkt langfristig die Kosten.

Wartungsplanung

Für die optimale Funktion Ihrer Lagerbeleuchtung benötigen Sie einen soliden Wartungsplan. Hallenstrahler, insbesondere moderne LED-Modelle wie der dimmbare Hallenstrahler von Rackorapro, vereinfachen diesen Prozess deutlich im Vergleich zu herkömmlichen Beleuchtungssystemen. Sie profitieren von einer längeren Lebensdauer, was weniger Austausch und Ausfallzeiten bedeutet. Die meisten LED-Hallenstrahler erreichen eine Lebensdauer von über 50.000 Stunden, sodass Sie weniger Zeit mit Leitersteigen oder Reparaturen verbringen müssen.

Erstellen Sie zunächst einen regelmäßigen Inspektionsplan. Prüfen Sie jede Leuchte auf Staubablagerungen, lose Verbindungen und Verschleißerscheinungen. Reinigen Sie Linsen und Gehäuse, um optimale Helligkeit zu gewährleisten. Nutzen Sie eine einfache Checkliste, um Ihre Wartungsarbeiten zu dokumentieren.

- Überprüfen Sie die Einrichtungsgegenstände vierteljährlich auf Staub und Schmutz.

- Testen Sie die intelligenten Steuerungen und Sensoren, um deren einwandfreie Funktion sicherzustellen.

- Prüfen Sie, ob die Lichter flackern oder schwächer werden, und tauschen Sie sie gegebenenfalls aus.

- Überprüfen Sie die Verkabelung und die Montagevorrichtungen auf Sicherheit.

Hochregalleuchten bieten einen einfacheren Zugang für Wartungsarbeiten. Dank ihrer Konstruktion lassen sich Leuchten auch in Umgebungen mit hohen Decken mühelos erreichen. Mithilfe von Hebezeugen oder Teleskopwerkzeugen können Sie die Leuchten reinigen und prüfen, ohne den laufenden Betrieb im Lager zu stören. Das spart Zeit und erhöht die Sicherheit Ihres Teams.

Intelligente Steuerungen und Präsenzmelder spielen eine Schlüsselrolle in Ihrem Wartungsplan. Sie können den Energieverbrauch und den Status der Leuchten zentral überwachen. Automatische Benachrichtigungen informieren Sie, sobald eine Leuchte gewartet werden muss. Sie können Helligkeit und Zeitpläne anpassen, um die Lebensdauer jeder Leuchte zu verlängern. Dieser proaktive Ansatz hilft Ihnen, unerwartete Ausfälle zu vermeiden.

Die dimmbare Hallenleuchte von Rackorapro ist für alle Spannungen geeignet, Feuchtraumtauglich und robust gebaut. Dank dieser Eigenschaften ist der Wartungsaufwand gering. Die lange Lebensdauer und hohe Energieeffizienz bedeuten seltenere Leuchtmittelwechsel und geringere Reparaturkosten. Zusätzlich profitieren Sie von einer 5-jährigen eingeschränkten Garantie, die Material- und Funktionsmängel abdeckt.

Tipp: Bei der Planung umfangreicher Upgrades oder Ersatzlieferungen können Sie von Rackorapros kostenlosem Versand, der Zufriedenheitsgarantie und den Mengenrabatten profitieren.

Sie sollten alle Wartungsarbeiten dokumentieren. Halten Sie Inspektionsdaten, Reparaturen und Austauschvorgänge fest. So erkennen Sie Muster und können zukünftige Modernisierungen planen. Mit einer vorausschauenden Wartung Ihrer Beleuchtungsanlage gewährleisten Sie ein sicheres und effizientes Lager.

Mit Hallenstrahlern, die über fortschrittliche Funktionen und umfassende Garantien verfügen, treffen Sie eine kluge Investition. Ihre Wartung wird einfacher, Ihre Kosten sinken und Ihr Lager bleibt hell und produktiv.

Die Zukunft der Lagerbeleuchtung

Intelligente Integration

Intelligente Integration wird in der Lagerbeleuchtung zum Standard. Moderne Systeme nutzen fortschrittliche Steuerungstechnik und drahtlose Technologien, um Ihre Anlage effizienter zu gestalten. Intelligente Sensoren erkennen Bewegungen und passen die Helligkeit automatisch an. Sie können Ihre Beleuchtung mit anderen intelligenten Technologien in Ihrem Gebäude vernetzen. Diese Integration hilft Ihnen, Energie zu sparen und die Sicherheit zu erhöhen.

- Erweiterte Lichtsteuerungsfunktionen ermöglichen die Verwaltung von Helligkeit und Zeitplänen.

- Die drahtlose Technologie ermöglicht eine einfache Installation und Aktualisierung.

- Intelligente Sensoren reagieren auf Anwesenheit und Tageslicht.

- Daten aus intelligenten Systemen helfen Ihnen, Bereiche zu finden, die mehr Licht oder Anpassungen benötigen.

- Nachhaltigkeitsbestrebungen fördern die Akzeptanz dieser intelligenten Funktionen.

Intelligente Beleuchtungssysteme erfassen Daten zu Nutzungsmustern. Diese Daten können analysiert werden, um den Energieverbrauch zu optimieren und die Lagerabläufe zu verbessern.

Neue Technologien

Neue Technologien in der Hallenbeleuchtung bieten Ihnen mehr Kontrolle und Effizienz. Viele Systeme verfügen heute über integrierte Sensorsteuerung, IoT-Anbindung und Echtzeit-Datenfeedback. Diese Funktionen helfen Ihnen, Energie zu sparen und einen reibungslosen Lagerbetrieb zu gewährleisten.

|

Technologie |

Beschreibung |

|---|---|

|

Integrierte Sensorsteuerung |

Das Licht schaltet sich ein, wenn Personen ankommen, und aus, wenn sie gehen, wodurch über 60 % Energie gespart werden. |

|

IoT-Interaktion |

Verbindet sich mit Lagerverwaltungssystemen für zonierte Beleuchtung und Fernüberwachung. |

|

Daten-Feedback |

Bietet Statusaktualisierungen in Echtzeit für Wartung und Leistung. |

Sie können Ihre Beleuchtung über Smartphone-Apps oder Gebäudemanagementsysteme steuern. Die Echtzeitüberwachung ermöglicht die Anpassung der Einstellungen an die Anwesenheit von Personen. Moderne Sensoren liefern Ihnen Datenanalysen zur Optimierung der Nutzung. Sie können die Lichtstärke feinjustieren, Zonen unabhängig voneinander steuern und Zeitpläne automatisieren, die zu Ihren Lagerzeiten passen.

Nachhaltigkeitstrends

Nachhaltigkeit prägt die Zukunft der Lagerbeleuchtung. LED-Hallenstrahler konzentrieren sich heute auf die Reduzierung von Energieverbrauch und Wartungskosten. Mit diesen effizienten Optionen tragen Sie zur Verringerung Ihres CO₂-Fußabdrucks bei. Viele Produkte sind recycelbar, was die Umweltbelastung reduziert. Dank ihrer langen Lebensdauer müssen LED-Leuchten seltener ausgetauscht werden, wodurch Ressourcen in Produktion und Vertrieb gespart werden.

- LED-Hallenstrahler minimieren Energieverbrauch und Wartungskosten.

- Sie helfen Ihnen, Ihre unternehmerischen Nachhaltigkeitsziele zu erreichen.

- Diese Leuchten verbrauchen weniger Energie als herkömmliche Modelle und reduzieren so Ihren CO2-Fußabdruck.

- Viele Produkte sind recycelbar, wodurch die Umweltbelastung verringert wird.

- Längere Lebensdauern bedeuten weniger Ersatzbedarf und weniger Abfall.

Mit der Einführung nachhaltiger Beleuchtung unterstützen Sie sowohl Ihre Geschäftsziele als auch die Umwelt.

Sie können Ihr Lager durch die Umrüstung auf moderne Hallenstrahler wie die von Rackorapro modernisieren. Diese Strahler bieten erhebliche Energieeinsparungen, erhöhen die Sicherheit und steigern die Produktivität. Die langfristigen Kostenvorteile sehen Sie unten:

|

Nutzen |

Beschreibung |

|---|---|

|

Energieeinsparungen |

Bis zu 80 % weniger Energieverbrauch, wodurch die Energiekosten sinken. |

|

Reduzierte Wartungskosten |

LEDs haben eine Lebensdauer von über 50.000 Stunden, wodurch Ersatz- und Arbeitskosten reduziert werden. |

|

Verbesserte betriebliche Effizienz |

Bessere Beleuchtung erhöht Sicherheit und Produktivität. |

Hallenstrahler unterstützen Ihre Nachhaltigkeitsziele und reduzieren Ihren CO₂-Fußabdruck. Experten empfehlen für hohe Decken eine hohe Lichtausbeute, Bewegungsmelder zur Energieoptimierung und eine Farbtemperatur von 5000 K für optimale Sicht. Bleiben Sie über neue Beleuchtungstechnologien informiert, um Ihr Lager effizient und zukunftssicher zu gestalten.

Häufig gestellte Fragen

Was ist eine Hallenleuchte?

Eine Hallenleuchte ist eine leistungsstarke Leuchte, die für Räume mit hohen Decken, wie beispielsweise Lagerhallen, konzipiert ist. Sie dient der hellen und gleichmäßigen Ausleuchtung großer Flächen.

Wie wähle ich die richtige Wattzahl für mein Lager aus?

Berücksichtigen Sie Ihre Deckenhöhe und die in den einzelnen Bereichen anfallenden Aufgaben. Die dimmbare Hallenleuchte von Rackorapro bietet Ihnen verschiedene Wattagen zur Auswahl, um Ihren Bedürfnissen gerecht zu werden.

Kann ich die Farbtemperatur der dimmbaren Rackorapro-Hallenleuchte einstellen?

Ja! Sie können zwischen 3500K, 4000K oder 5000K wählen. Diese Funktion hilft Ihnen, die optimale Beleuchtung für verschiedene Aufgaben oder Vorlieben zu schaffen.

Sind LED-Hallenstrahler energieeffizient?

Absolut. LED-Hallenstrahler verbrauchen weniger Strom als herkömmliche Leuchten. Sie sparen Energiekosten und reduzieren Ihren CO₂-Fußabdruck.

Wie lange ist die Lebensdauer von LED-Hallenstrahlern?

Die dimmbare Hallenleuchte von Rackorapro hat eine Lebensdauer von über 50.000 Stunden. Diese lange Lebensdauer bedeutet weniger Austausch und geringeren Wartungsaufwand.

Ist die Installation kompliziert?

Nein. Dank der universellen Spannungskompatibilität lassen sich diese Leuchten problemlos installieren. Die meisten Anwender empfinden die Installation als unkompliziert, insbesondere beim Austausch alter Leuchten.

Welche Garantie bietet Rackorapro an?

Für die dimmbare Hallenleuchte von Rackorapro erhalten Sie eine 5-jährige eingeschränkte Garantie. Diese Garantie gibt Ihnen Sicherheit und schützt Ihre Investition.