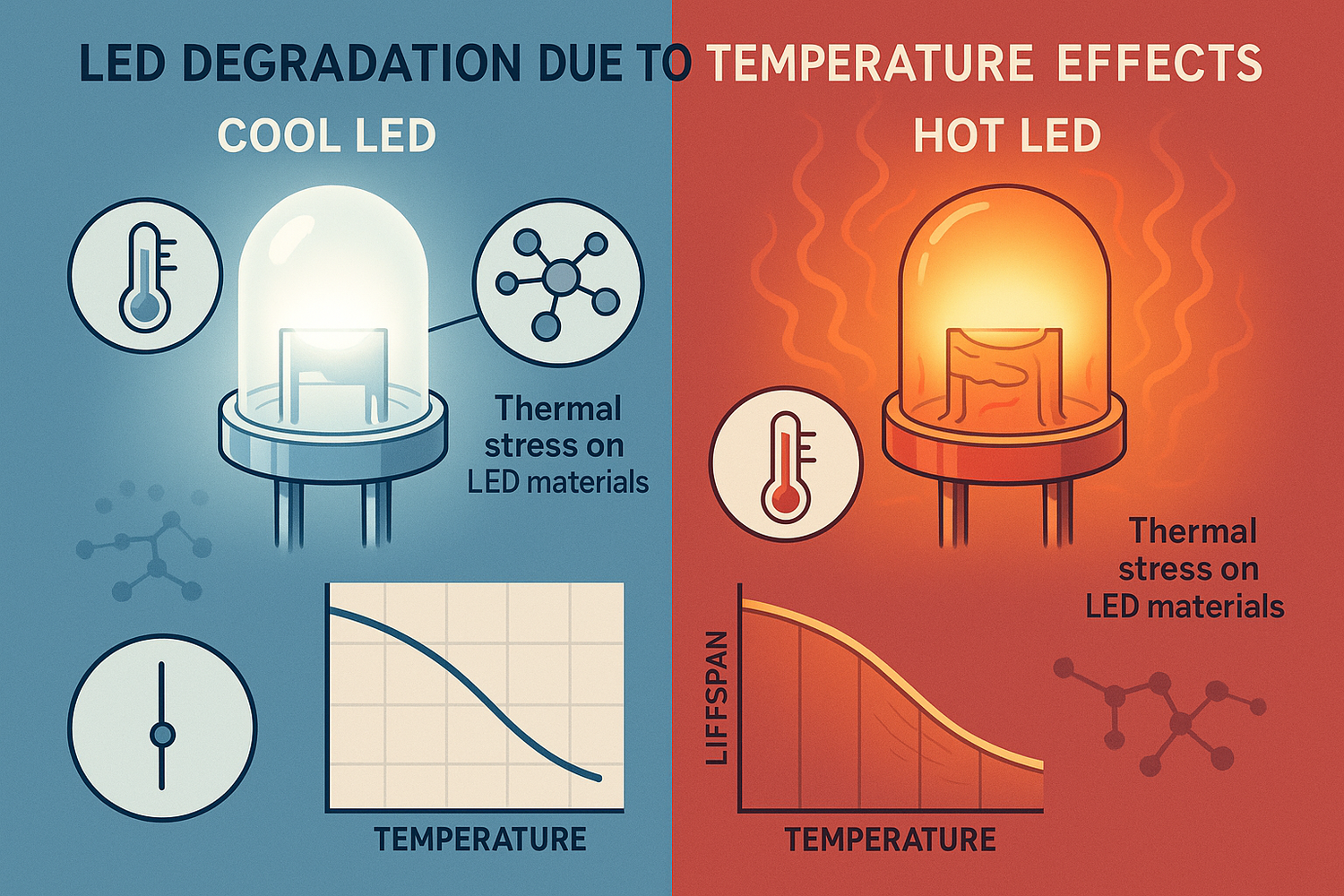

Temperature plays a critical role in led degradation. High temperatures can drastically reduce the lifespan of an led by up to six times, causing issues such as decreased brightness, color shifts, and physical damage. Low temperatures have less effect on the led itself but may impact batteries within fixtures. Frequent temperature changes accelerate led degradation and shorten lifespan. Quality design and materials, like those found in Rackora’s products, help maintain led performance and extend operating life, even in challenging environments.

Key Takeaways

- High temperatures speed up LED degradation, causing brightness loss, color shifts, and shorter lifespan.

- Low temperatures usually improve LED performance but can harm batteries and cause material damage in extreme cold.

- Frequent temperature changes create stress that damages LED components and reduces their life.

- Good heat management with heat sinks, quality materials, and smart fixture design helps keep LEDs cool and lasting longer.

- Rackora’s LED flood lights use advanced heat dissipation and protection features to perform well in harsh temperature conditions.

- Solar lighting systems need special temperature controls to protect panels and batteries for reliable operation.

- Proper installation, regular cleaning, and maintenance prevent overheating and extend LED lifespan.

- Choosing LEDs with strong heat sinks, high IP ratings, and from trusted brands ensures better durability in extreme temperatures.

LED Degradation and Temperature

High Temperatures

High operating temperatures have a direct and significant impact on led degradation. Technical research shows that even a small increase in temperature, such as from 35.6°C to 37.4°C, can cause a 13% decrease in phosphor conversion efficiency and a noticeable drop in light intensity. When led luminaires operate in high ambient temperature environments, the junction temperature inside the device rises. This increase accelerates electro-thermal stress and leads to faster degradation of materials.

Laboratory tests reveal that high temperatures, such as 75°C, can temporarily reduce light output by 5% to 70%. Prolonged exposure results in permanent lumen degradation, which shortens the lifespan of led lights. High operating temperatures also cause color shifts, sometimes turning white light into a bluish hue. Poor-quality materials and inadequate heat management make these effects worse.

Commercial led products, like Rackora’s Wholesale High-Efficiency 50-600W LED Flood Lights, use advanced heat management techniques to maintain optimal performance and extend the lifespan of led lights, even in demanding conditions.

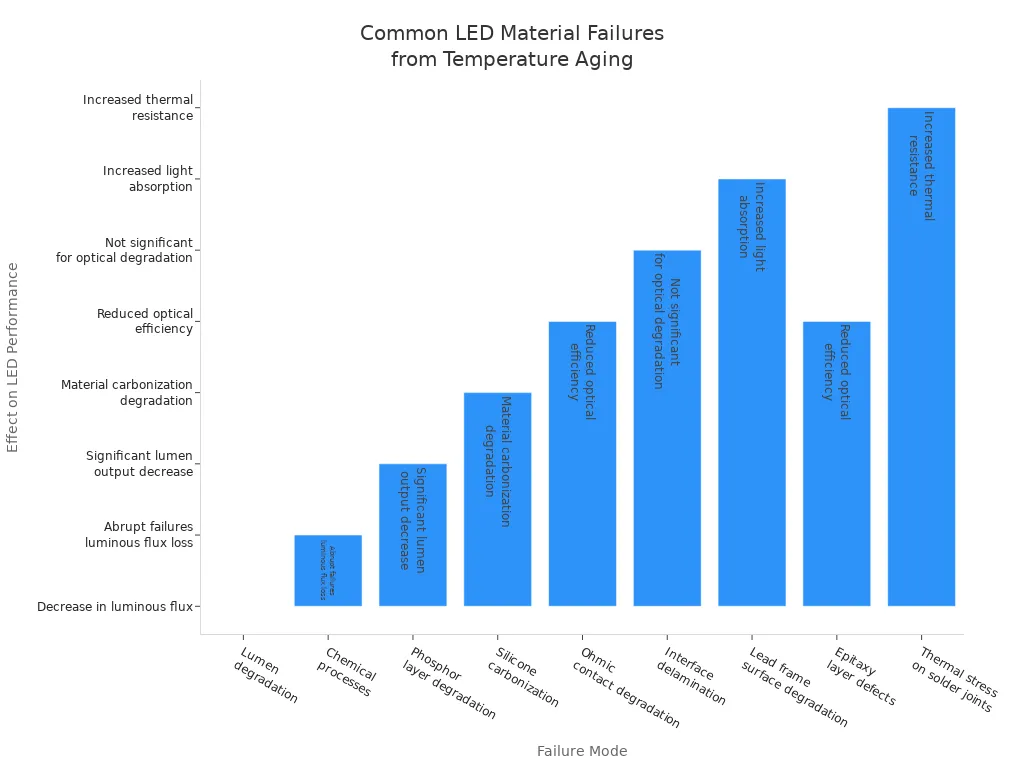

Common failure modes at high operating temperatures include:

- Browning and detachment of encapsulant materials.

- Increased thermal resistance and mechanical stress.

- Moisture ingress due to gaps created by thermal expansion.

- Rapid lumen degradation, especially in white leds with phosphor layers.

Effective heat management, such as using heat sinks and robust fixture designs, helps prevent these issues and supports the longevity of led luminaires.

Low Temperatures

Low temperatures affect led degradation differently. LEDs generally perform better in cold environments, showing increased brightness and reduced degradation rates. Cold conditions allow leds to start instantly and reduce thermal stress on drivers and diodes, which improves performance and extends the lifespan of led lights.

However, extremely low temperatures can create risks for outdoor installations:

- Materials in led modules and cabinets shrink inconsistently, causing gaps and fractures.

- Waterproof seals may shrink, increasing the risk of water ingress.

- Protective cable layers can become brittle and break, leading to short circuits or fire.

- Electronic components may fail to start or operate properly.

Modern leds are designed to handle a wide range of temperatures, but persistent exposure to cold can still cause premature failure. Using low-temperature resistant materials and protective coatings helps prevent damage. Regular maintenance, such as checking for moisture and loose wiring, is essential for reliable operation.

Fluctuations and Stress

Frequent temperature fluctuations, known as thermal cycling, place additional stress on led components. Materials inside the led expand and contract at different rates, which leads to thermal stress and structural deformation. This stress can reach up to 347 MPa in aluminum cases and is a primary cause of module failure.

A 10°C increase in junction temperature can reduce the lifespan of led lights by about 50%. For example, leds operating at 85°C may last 25,000 hours, while those at 65°C can reach 50,000 hours. Thermal cycling also affects the thermal resistance of led packages, impacting overall performance and reliability.

Effective heat management and careful material selection are crucial for minimizing thermal stress and supporting the longevity of led luminaires in environments with frequent temperature changes.

Commercial led products, such as Rackora’s flood lights, are engineered with advanced heat management and durable materials to withstand temperature fluctuations. These features help maintain led performance and extend the lifespan of led lights in both indoor and outdoor settings.

Mechanisms of Degradation

Junction Temperature

Junction temperature plays a central role in determining how quickly an LED degrades. Scientific models show that most LED failure modes are thermally activated and follow an Arrhenius-type pattern. This means the rate of degradation increases exponentially as temperature rises. Junction temperature, not just the ambient temperature, drives this process. When an LED operates, electrical energy converts into light and heat. If the heat dissipation is poor, the junction temperature climbs. This self-heating effect creates a feedback loop, making the LED degrade even faster.

Studies confirm that higher junction temperatures directly reduce LED reliability and performance. For example, a junction temperature of 117°C can cause a 20% drop in luminous flux, while 135°C marks the point where performance deteriorates rapidly and irreversibly.

|

Junction Temperature (°C) |

Effect on LED Performance |

|---|---|

|

117 |

20% decrease in luminous flux (notable degradation begins) |

|

135 |

Maximum junction temperature; rapid, irreversible degradation |

LEDs stressed within safe junction temperature limits show minimal degradation. However, when the temperature exceeds these limits, failures such as silicone cracking, solder degradation, and catastrophic light loss occur. Effective heat dissipation is essential to keep the junction temperature within safe boundaries and ensure long-term LED performance.

Material Aging

Material aging in LEDs accelerates when exposed to high temperature over time. Aging tests reveal that prolonged heat increases thermal resistance and junction temperature, which reduces heat dissipation efficiency. This process causes several types of physical damage:

- Thermal expansion mismatches between materials lead to solder joint cracks and gold wire breaks.

- Silicone and epoxy resins yellow and harden, blocking light and trapping more heat.

- Semiconductor materials develop defects, increasing leakage current and reducing efficiency.

- Electrolytic capacitors in the driver circuit lose lifespan as the electrolyte evaporates faster.

- The Arrhenius model shows that chemical reaction rates double for every 10 to 15°C increase in temperature.

LEDs with better heat dissipation performance, such as those using nano-Ag paste, maintain lower thermal resistance and age more slowly. The cycle of rising temperature and reduced heat dissipation creates a vicious circle, accelerating the aging process.

Phosphor Degradation

Phosphor degradation is another key mechanism by which temperature affects LED performance. High temperature accelerates the breakdown of the phosphor layer, which is responsible for converting blue or ultraviolet light into visible white light. As the phosphor degrades, the LED loses brightness and the color shifts, often becoming less stable.

Phosphor degradation happens faster when heat dissipation is inadequate. Elevated phosphor temperatures cause hydrolysis-based darkening and quantum efficiency losses. This creates a feedback loop: as the phosphor becomes less efficient, more heat builds up, which further accelerates degradation. Some phosphor materials, like YAG:Ce3+, show better stability, but most still suffer from reduced efficiency and mechanical damage under high temperature and humidity.

Managing Temperature

Heat Sinks

Heat sinks play a vital role in heat dissipation for LED systems. Manufacturers use materials like aluminum and copper because they conduct heat away from the LED chip efficiently. Radial-finned heat sinks and PCM-filled designs lower junction temperature, which extends LED lifespan. For example, a radial-finned heat sink can reduce junction temperature from 84°C to 55°C at 10 W input power. PCM-filled heat sinks decrease thermal resistance by over 38%, further improving heat dissipation performance.

Increasing the surface area and optimizing fin geometry enhances heat dissipation. Forced airflow, even at low velocities, can reduce junction temperature by up to 30%. These improvements support effective heat management and prevent rapid degradation. Rackora’s LED Flood Lights use die-cast aluminum housings, which provide high heat dissipation performance and maintain quality in demanding environments.

|

Heat Dissipation Method |

Cooling Efficiency |

Implementation Complexity |

|---|---|---|

|

Aluminum profiles/channels |

Medium to High |

Low |

|

Thermal adhesive mounting |

Medium |

Low |

|

Active cooling with fans |

Very High |

Medium |

|

Reduced power operation/dimming |

Medium |

Low |

|

Heat sink compound application |

High |

Medium |

Tip: Increasing airflow and using advanced heat sink designs can lower LED junction temperature, improving both efficiency and lifespan.

Fixture Design

Fixture design directly impacts heat management and LED longevity. Designers select materials with high thermal conductivity, such as aluminum and copper, to serve as heat sinks. These materials draw heat away from the LED module, supporting effective heat dissipation. Polycarbonate diffusers resist heat buildup near the light source, maintaining light quality.

Optimized internal thermal pathways and strategic heat sink placement further enhance heat dissipation performance. Custom-designed heat sinks with advanced geometry can increase LED lifespan by 30% and reduce maintenance costs by 25%. Rackora’s LED Flood Lights feature robust construction and IP65-rated enclosures, which protect against dust and water ingress. This design ensures quality and reliable heat management, even in harsh outdoor environments.

Manufacturers also use thermal interface materials to reduce resistance between the LED and heat sink. These materials improve heat transfer and support effective heat management. By integrating thermal management early in the design process, engineers extend the lifespan of LEDs and maintain consistent performance.

Environmental Controls

Environmental controls help maintain optimal temperature for LED installations. Open-air fixture designs improve ventilation and reduce overheating compared to enclosed shoebox-style fixtures. Proper ventilation and heat management are essential in extreme temperature environments.

Commercial settings benefit from dynamic environmental sensing and control systems. These systems use PID algorithms to adjust LED brightness and color temperature based on ambient temperature. Centralized control systems compute optimal output ratios and communicate wirelessly to individual drivers, ensuring uniform thermal conditions.

Rackora’s LED Flood Lights offer wide voltage compatibility, which allows them to operate efficiently under varying electrical conditions. This feature reduces the risk of overheating and electrical stress, supporting effective heat management. The IP65 rating protects against moisture and debris, preventing damage and maintaining quality in challenging environments.

Active heat dissipation systems, such as forced convection cooling, further enhance heat dissipation performance. These systems maintain uniform thermal management in multi-channel LED setups, ensuring consistent color output and reliable operation over time.

Note: Combining heat sinks, optimized fixture design, and environmental controls creates a comprehensive approach to effective heat management in LED installations.

Product Solutions by Rackora

Flood Lights Features

Rackora’s Wholesale High-Efficiency 50-600W LED Flood Lights deliver advanced solutions for temperature-related degradation. The design focuses on maintaining high led quality in demanding environments. These flood lights feature a luminous efficacy of 160 lumens per watt, which means they produce more light with less energy. This efficiency reduces heat generation, helping to preserve the quality of the led over time.

The IP65 protection rating ensures that each fixture is dust-tight and resistant to water jets. This environmental sealing keeps moisture and debris out, preventing damage that could worsen temperature-related failures. The wide voltage range (100-277V AC) allows the lights to operate reliably across different electrical systems. This stability reduces the risk of overheating and electrical faults, supporting consistent led quality.

Rackora uses high thermal conductivity materials, such as die-cast aluminum, to optimize heat dissipation. This approach helps maintain lower junction temperatures and extends the lifespan of the led.

|

Feature |

Benefit for Temperature Management |

|---|---|

|

High luminous efficacy |

Less heat, better energy efficiency |

|

IP65 protection |

Prevents moisture and dust ingress |

|

Wide voltage range |

Stable operation, reduces overheating |

|

Aluminum housing |

Improves heat dissipation |

Application Scenarios

Rackora’s flood lights suit a variety of commercial and industrial settings. Warehouses, sports facilities, and parking lots often face temperature extremes. These environments demand lighting solutions that maintain quality and reliability. The flood lights offer flexible wattage options from 50W to 600W and color temperatures from 3000K to 7000K. This versatility allows users to select the right product for each scenario, ensuring optimal led quality.

In outdoor installations, the IP65 rating protects against rain, dust, and temperature fluctuations. Indoor spaces benefit from the wide voltage compatibility, which ensures stable performance even when electrical conditions change. The high color rendering index (RA>70) supports visibility and safety, further enhancing the quality of the lighting.

Tip: Choosing flood lights with high luminous efficacy and robust protection features helps maintain lighting quality in both indoor and outdoor environments.

Reliability in Harsh Conditions

Rackora engineers its flood lights for reliability in harsh conditions. The combination of high luminous efficacy, IP65 protection, and wide voltage range directly addresses common temperature-related challenges. These features work together to prevent brightness degradation, color shifts, and early failure.

The quality of the materials and design ensures that the led maintains performance even during heat waves or cold snaps. Overheat protection in the driver ICs helps regulate current output, preventing damage and supporting long-term led quality. The environmental sealing keeps out moisture and debris, which can cause electrical and mechanical failures.

Rackora’s commitment to quality means that each flood light undergoes rigorous testing for durability and performance. Users can trust these products to deliver consistent led quality, even in the most demanding environments.

Solar Lighting and Temperature

Power Optimization

Solar street lighting systems face unique challenges due to changing temperature conditions. High temperatures in regions like Arizona and Texas can reduce photovoltaic efficiency by up to 0.5% for every 1°C increase. When panel temperatures exceed 80°C, efficiency losses can reach over 20%. To address this, engineers use passive thermal designs such as ventilation channels and reflective coatings. Some systems include active cooling, like micro-fans or phase change materials, to manage heat.

Proper panel orientation and regular cleaning help maximize sunlight exposure and charging efficiency. Rackora’s solar street light power optimization solution uses advanced algorithms and dynamic management to match photovoltaic output with battery storage and load demand. This approach ensures stable lighting even during heatwaves or cold snaps. In cold climates, panel tilt and design prevent snow accumulation, maintaining reliable operation throughout winter.

|

Aspect |

Impact / Strategy |

|---|---|

|

Photovoltaic Efficiency Loss |

Decreases by ~0.4%-0.5% per 1°C increase; >20% loss when panel temperature >80°C |

|

Passive Thermal Design |

Ventilation, reflective coatings, honeycomb heat dissipation |

|

Active Cooling Systems |

Micro-fans, phase change materials |

|

Panel Orientation |

Maximizes sunlight, sheds snow |

Battery Life

Temperature extremes have a direct effect on battery life in solar lighting systems. In hot climates, batteries require weatherized enclosures and thermal management to prevent overheating. Burying batteries underground or using thermal conductive materials helps stabilize temperature and extend battery lifespan. In cold regions, battery capacity can drop to 50% at -20°C and below 20% at -40°C without proper mitigation.

Modern systems use low-temperature lithium batteries, which retain over 80% capacity at -20°C. Integrated thermal chambers and self-heating systems keep batteries above freezing, ensuring reliable operation. Multi-layer insulation and active heating further protect against cold. Rackora’s solution includes battery management strategies that optimize charging and discharging, preventing deep discharges and overcharging. Regular maintenance and monitoring with battery management systems (BMS) help extend battery life and system reliability.

Smart Controls

Smart controls play a key role in adapting solar lighting to temperature changes and seasonal variations. Advanced controllers adjust lighting schedules based on ambient conditions, reducing energy use during shorter daylight hours. Sensors and timers automatically dim or brighten lights, optimizing power consumption and extending battery life.

Hybrid systems that combine solar with wind or grid backup increase reliability during extreme weather. Flexible thin-film panels and bifacial technology improve power generation, even with snow cover. Rackora’s power optimization solution integrates smart controls to dynamically allocate energy, prioritize critical loads, and maintain stable lighting performance. These technologies ensure that solar street lights operate efficiently and reliably across a wide range of temperature conditions.

Tip: Regularly inspect and maintain solar lighting systems to detect power leaks, faulty parts, or insulation issues. This practice supports long-term reliability and performance.

Best Practices

Installation Tips

Proper installation plays a crucial role in minimizing temperature-related LED degradation, especially in outdoor environments. Installers should follow these guidelines to ensure optimal performance and longevity:

- Avoid placing LED fixtures near heat sources such as ovens, industrial machinery, or HVAC exhausts. This reduces unnecessary heat buildup.

- Select LED fixtures rated for high-temperature environments. These products withstand thermal stress better.

- Position outdoor LEDs to limit direct sunlight exposure. Use shading structures when possible to prevent overheating.

- Choose weather-resistant materials, including UV-resistant lenses and corrosion-proof housings, to protect LEDs from environmental stress.

- Install LEDs in well-ventilated fixtures. Open or vented designs promote airflow and enhance heat dissipation.

- Maintain proper spacing around fixtures. This prevents heat from becoming trapped against walls, ceilings, or insulation.

- Prefer fixtures made from aluminum or other metals for better thermal conductivity compared to plastic.

- In high-temperature or industrial outdoor settings, consider active cooling solutions such as fan-assisted or liquid cooling systems.

- Clean fixtures regularly to remove dust, which can obstruct heat dissipation.

- Use thermal sensors to monitor temperature and schedule routine maintenance. This helps prevent overheating and extends LED lifespan.

Tip: Good airflow and regular cleaning are simple ways to keep LEDs cool and efficient.

Maintenance

Consistent maintenance supports temperature management and extends the lifespan of LED lighting systems. The following steps help maintain optimal performance:

- Clean LED fixtures regularly to remove dust and dirt. This prevents overheating by allowing heat to dissipate efficiently.

- Ensure proper ventilation around fixtures. Avoid placing LEDs near heat sources to protect internal components.

- Use voltage stabilizers or surge protectors. Stable power supply prevents damage from electrical fluctuations.

- Minimize frequent on/off cycling. This reduces stress on LED electronics and prevents premature degradation.

- Check heat dissipation effectiveness. A simple touch test can help identify overheating issues.

- Schedule professional maintenance checks. These checks help control temperature and humidity, prolonging operational life.

Regular maintenance not only keeps LEDs bright but also protects sensitive components like chips and driver circuitry.

Product Selection

Selecting the right LED products for environments with extreme temperature variations ensures reliable performance and durability. Consider these criteria:

- Choose LED fixtures designed to operate within recommended temperature ranges. This prevents performance loss from extreme heat or cold.

- Select products with strong, effective heat sinks. Proper heat dissipation prevents overheating and extends lifespan.

- Look for moisture-resistant fixtures with adequate IP ratings, such as IP65 or higher. Sealed designs prevent damage from humidity and moisture ingress.

- Use vapor-tight fixtures in high-humidity or moisture-prone locations. This adds another layer of protection.

- Ensure proper ventilation around installed fixtures. Good airflow helps manage heat buildup.

- Prefer products from reputable manufacturers that offer warranties. Quality components and reliable support matter in harsh conditions.

- For low-temperature environments, select LEDs specifically designed for cold storage or outdoor winter use.

|

Selection Criteria |

Benefit |

|---|---|

|

High IP rating (IP65+) |

Protects against dust and moisture |

|

Strong heat sinks |

Improves heat dissipation |

|

Quality manufacturer |

Ensures reliability and warranty support |

Note: Investing in quality LED fixtures may cost more initially, but it leads to long-term energy savings and reduced maintenance.

Temperature extremes can shorten the lifespan of led lights and reduce the longevity of led luminaires. Effective temperature management helps maximize reliability and performance. Rackora’s products use dense cast aluminum housings, vent plugs, and high-temperature resistant components to support longer lifespan. To extend the lifespan of led lights, users should keep fixtures away from heat sources, maintain clean cooling fans, and ensure proper ventilation. Regular monitoring and prompt action against overheating protect internal electronics and preserve lighting quality.

- Use aluminum housings and ceramic insulation for rapid heat dissipation.

- Avoid placing fixtures near sunlight or industrial heat.

- Incorporate vent plugs to prevent condensation.

- Select high temperature resistant power supply components.

- Operate LEDs below nominal power levels.

- Separate electronics from radiators.

- Design thick-walled bodies for insulation.

- Use multiple power supplies to reduce overheating.

- Implement efficient diode polarization and power settings.

Prioritizing temperature management during installation and maintenance ensures a longer lifespan and reliable operation for every LED product.

FAQ

How does high temperature affect LED lifespan?

High temperatures speed up LED degradation. The LED loses brightness faster and may fail early. Proper heat management helps maintain performance and extends lifespan.

Can LEDs work in freezing temperatures?

LEDs can operate in cold environments. Cold temperatures usually improve LED efficiency. However, extreme cold may damage seals or wiring. Using weather-resistant fixtures prevents these issues.

Why is junction temperature important for LEDs?

Junction temperature measures the heat at the LED’s core. High junction temperature causes rapid material aging and light loss. Keeping this temperature low ensures reliable LED operation.

What features help LEDs handle temperature extremes?

Features like aluminum housings, IP65 protection, and wide voltage compatibility help LEDs resist temperature stress. These features improve heat dissipation and prevent moisture damage.

How often should users maintain LED fixtures?

Users should clean and inspect LED fixtures every three to six months. Regular maintenance removes dust, checks for damage, and ensures proper ventilation.

Do solar-powered LEDs need special temperature management?

Solar-powered LEDs require careful temperature management. High heat reduces solar panel efficiency. Cold affects battery performance. Smart controls and thermal design help maintain stable lighting.

What is the best way to select LEDs for outdoor use?

Select LEDs with high IP ratings, strong heat sinks, and durable materials. Choose products from reputable brands like Rackora for reliable performance in harsh conditions.

Can temperature fluctuations cause LED failure?

Frequent temperature changes create thermal stress. This stress can crack materials and reduce LED lifespan. Quality design and materials help LEDs withstand these fluctuations.