Introduction: Safety Considerations for Gas Station Lighting

Gas stations are classified as flammable and explosive hazardous locations. Their lighting systems must meet both functional illumination and safety protection requirements. According to the National Fire Protection Association (NFPA), electrical system failures accounted for 34% of gas station fire incidents in North America between 2018 and 2022, with sparks and overheating from lighting equipment being a primary cause. While solar lighting offers energy-saving benefits, its battery energy storage systems, electrical wiring, and heat dissipation from light sources can pose safety risks if not properly designed.

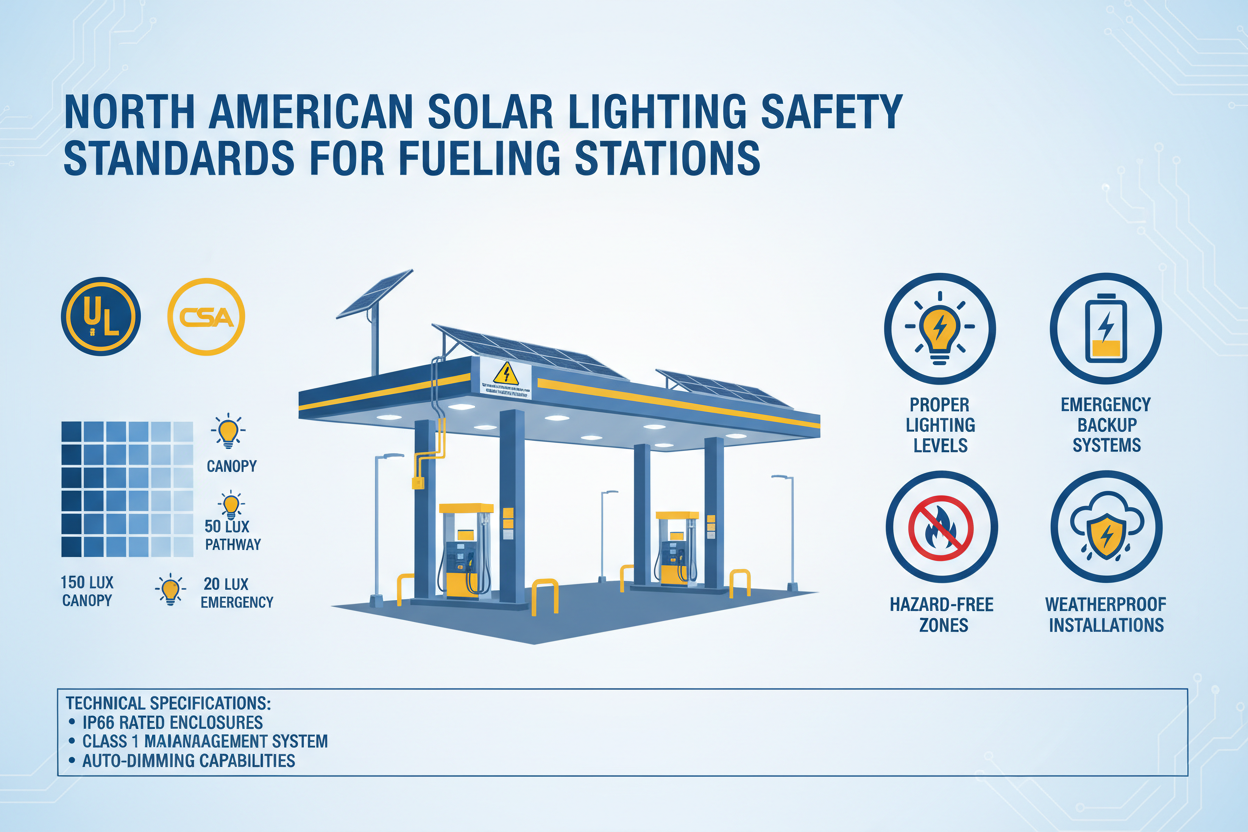

This article systematically explains the safety standard framework, technical specifications, installation requirements, and maintenance procedures for solar lighting in North American gas stations. It assists owners, contractors, and designers in balancing safety and energy efficiency while complying with authoritative standards such as NFPA, OSHA, and UL.

1. Safety Standard System for Gas Station Solar Lighting

1.1 Core Standards and Regulations

Solar lighting systems for gas stations must comply with the following North American standards, which directly impact system design:

| Standard/Regulation | Issuing Authority | Core Requirements |

|---|---|---|

| NFPA 30 | National Fire Protection Association | Specifies installation standards for electrical equipment in flammable liquid storage and handling areas, including explosion-proof ratings for lighting |

| OSHA 1910.106 | Occupational Safety and Health Administration | Defines hazardous area classification (Class I, Division 1/2) and corresponding electrical equipment safety standards |

| UL 844 | Underwriters Laboratories | Testing standard for explosion-proof performance of luminaires, covering structural strength, temperature limits, spark protection, etc. |

| NEC Article 514 | National Electrical Code | Detailed specifications for gas station electrical system design and installation, including grounding, wiring, and equipment selection |

| IES RP-18 | Illuminating Engineering Society | Illuminance standards for various gas station areas (e.g., 30 fc at fuel dispensers, 10 fc for walkways) and glare control requirements |

Key Terminology Explained:

- Hazardous Area Classification (OSHA 1910.106): Gas stations are typically classified as Class I, Division 2 areas (where flammable vapors may exist but not normally in explosive concentrations). Lighting equipment must meet corresponding explosion-proof ratings (e.g., UL 844 Class I, Div 2).

- Surface Temperature Limits: According to NFPA 30, luminaire surface temperatures must be below the ignition temperature of surrounding combustible materials (gasoline ignites at 280°C, so luminaire surface temperatures are typically limited to 135°C or lower).

1.2 Standard Updates

- 2023 NFPA 30 Revision: Added "Renewable Energy System Installation Guidelines," specifying safe distance requirements for solar panels and energy storage batteries (at least 15 feet from tank areas).

- UL 844 7th Edition: Enhanced testing requirements for LED luminaire heat dissipation design, added "thermal runaway protection" clause requiring battery energy storage systems to have automatic over-temperature cutoff.

- California Title 24-2025: Requires gas station lighting systems to have a Lighting Efficacy Ratio (LER) ≥2.0 and solar energy contribution ≥30%, promoting the integration of low-power explosion-proof LEDs with solar power.

2. Safety Design Specifications for Gas Station Solar Lighting Systems

2.1 System Architecture Safety Requirements

Gas station solar lighting systems must adopt an "intrinsically safe" design, with core components including explosion-proof luminaires, flameproof controllers, sealed energy storage batteries, and lightning protection grounding systems. Specific requirements are as follows:

(1) Light Source and Luminaire Selection

- Explosion-Proof Rating: Must be UL 844 Class I, Division 2 certified. Recommended types include Increased Safety (Ex e) or Flameproof (Ex d) luminaires. Ordinary open luminaires are prohibited.

- Light Source Type: Prioritize LED light sources for their low surface temperature (≤90°C), low energy consumption (60% more efficient than metal halide), and no filament fracture risk. Example: Cree XLamp XP-G3 LED provides 130 lm/W efficacy at 30W with a surface temperature of only 75°C.

- Optical Design: Luminaires must have directional light distribution (e.g., Type III beam angle) to avoid glare for drivers (Unified Glare Rating UGR ≤22) and minimize light pollution (meeting Dark Sky Association requirements).

(2) Energy Storage System Safety Design

- Battery Type: Lead-acid batteries are prohibited due to electrolyte leakage risk. Lithium Iron Phosphate (LiFePO4) batteries are recommended, featuring overcharge protection (OCV ≤3.65V), over-discharge protection (SOC ≥20%), and short-circuit protection.

- Installation Location: Energy storage batteries must be installed in explosion-proof enclosures, positioned ≥10 feet from fuel dispensers and ≥25 feet from tank vents (per NFPA 30). Example: Tesla Powerwall 2, UL 9540 certified, can be used directly in Class I, Div 2 areas.

- Capacity Configuration: Must meet lighting demands for 5 consecutive cloudy/rainy days (based on 12 hours of daily operation), with an additional 20% safety margin. Example: A 15W LED luminaire consumes 0.18 kWh daily, requiring 0.9 kWh for 5 days; configure a 1.1 kWh battery (e.g., 48V/23Ah LiFePO4 battery pack).

(3) Photovoltaic (PV) Module Installation Specifications

- Safe Distances: Solar panel edges must be ≥5 feet from gas station boundary walls and ≥3 feet from building roofs to avoid localized overheating from shading (hot spot effect).

- Tilt and Orientation: According to NREL data, optimal tilt for most North America (latitude 30°-45°N) is 35°-40°, facing true south to maximize generation (e.g., Arizona annual irradiance 6.5 kWh/m²/day, increasing PV efficiency by 12%).

- Structural Strength: Must withstand wind loads ≥120 mph (ASCE 7-16) and snow loads ≥30 psf. Mounting structures should use hot-dip galvanized steel (thickness ≥2mm) to prevent corrosion (additional polyamide coating required in coastal areas).

2.2 Electrical Safety Protection

(1) Grounding and Lightning Protection System

- Grounding Resistance: System grounding resistance must be ≤5Ω (NEC Article 250). Use a common grounding grid (PV panels, luminaires, battery share grounding electrode). Ground conductor cross-section ≥10 AWG (copper cable).

- Surge Protection: Install Class I/II Surge Protective Devices (SPDs) at PV array output, controller input, and luminaire power input. Response time ≤25 ns, maximum discharge current ≥20 kA (UL 1449 4th Edition). Example: Phoenix Contact VAL-MS 3000 SPD suitable for gas station environments.

(2) Wiring and Connections

- Cable Type: Use armored cable (MC-HL) or explosion-proof flexible conduit. Insulation temperature rating ≥90°C, voltage rating ≥600V. PVC cables are prohibited (prone to aging and cracking).

- Connection Method: All joints must use explosion-proof sealed connectors (UL 1203 certified), threaded engagement length ≥5 turns to ensure no spark leakage. Example: Appleton EXJ series connectors for Class I, Div 2 areas.

(3) Control and Monitoring System

- Intelligent Shutdown: System must have Remote Emergency Power Off (EPO) functionality, integrated with gas station fire protection system to cut all lighting power during fire (response time ≤100 ms).

- Temperature Monitoring: Install PT100 temperature sensors inside battery and controller enclosures for real-time monitoring (normal operating temperature -40°C to +65°C). Automatic shutdown if temperature exceeds limits (e.g., activate cooling fan at ≥55°C, cut output at ≥65°C).

3. Installation and Acceptance Procedures

3.1 Pre-Construction Preparation

-

Drawing Approval: Submit detailed design drawings to local Authority Having Jurisdiction (AHJ) for approval, including:

- Hazardous area classification diagram (marking Class I, Div 1/2 boundaries);

- System wiring diagram (including grounding, SPD locations, cable specifications);

- Equipment layout (installation locations and safe distances for PV panels, luminaires, batteries).

- Qualification Requirements: Personnel must hold NEC certification (e.g., Certified Electrical Worker) and be familiar with NFPA 30 and OSHA 1910.106. Explosion-proof equipment installation must be performed by UL-certified professionals.

3.2 Key Installation Steps

(1) Foundation Construction

- Luminaire foundations: Concrete cast (C30 strength, 500mm×500mm×600mm dimensions) with embedded grounding electrode (φ20mm×2.5m galvanized steel pipe). Foundation top 150mm above ground to prevent water accumulation.

- PV mounting foundations require geotechnical survey, bearing capacity ≥200 kPa. Use pile foundations in soft soil (e.g., φ100mm×2m helical piles) to prevent settlement-induced component deformation.

(2) Equipment Installation

- Luminaire mounting height: ≥4.5m at fuel dispensers to avoid vehicle impact; ≥6m in tank areas for comprehensive coverage. Install with 5° tilt to prevent water accumulation on luminaire surface.

- Battery enclosure fixation: Use expansion bolts (M12×100mm) fixed to concrete foundation. Reliably connect enclosure grounding terminal to grounding grid (copper bar cross-section ≥35 mm²).

3.3 Acceptance Testing

-

Electrical Safety Tests:

- Insulation resistance test: Line-to-ground insulation resistance ≥100 MΩ (using 500V megohmmeter);

- Grounding resistance test: Measure using four-pole method, grounding grid resistance ≤5Ω;

- Explosion-proof performance test: Pass UL 844 spark test (apply 1.5x rated voltage for 1 minute, no spark generation).

-

Lighting Performance Tests:

- Illuminance test: Use spectroradiometer (e.g., Konica Minolta T-10A) to measure illuminance: ≥30 fc at dispensers, ≥20 fc in tank areas, ≥10 fc for walkways;

- Glare test: Measure UGR, UGR ≤22 in fueling areas, complying with IES RP-18.

4. Maintenance and Troubleshooting

4.1 Routine Maintenance Schedule

| Maintenance Item | Frequency | Tasks |

|---|---|---|

| PV Panel Cleaning | Monthly | Clean with neutral detergent (pH 6-8) and soft cloth to remove dust, oil (0.5% efficiency loss per cm² of dust) |

| Luminaire Surface Inspection | Quarterly | Check explosion-proof housing for cracks, sealant aging; replace damaged seals (fluoroelastomer recommended, oil and temperature resistant) |

| Battery SOC Monitoring | Monthly | Check battery status via BMS; manually charge if SOC <20% to prevent over-discharge (shortens battery life by 30%) |

| Grounding Resistance Test | Semi-Annually | Test before rainy season; if ≥10Ω, add reducing agent (e.g., bentonite, can reduce to <5Ω) |

| Lightning Protection Check | Annually | Test SPD residual voltage (should be ≤1.5 kV); replace failed SPDs (typical lifespan 5-8 years) |

4.2 Common Troubleshooting

(1) Luminaire Not Lighting

-

Troubleshooting Steps:

- Check controller output voltage (normal 48V DC); if 0V, possible battery over-discharge or BMS protection;

- Measure luminaire input voltage; if normal (e.g., 24V DC), LED driver likely faulty, replace (recommended: Mean Well LDD-30H driver, UL 844 certified);

- If voltage abnormal, check for loose or oxidized wire connections (clean oxidation with sandpaper, re-tighten).

(2) Battery Swelling

- Cause: Overcharging (charger fault) or excessive temperature (ambient >65°C);

- Solution: Immediately deactivate and replace battery; check BMS overcharge protection (set charge cutoff voltage 48V±0.5V); add ventilation holes to battery enclosure (≥10 holes per m², diameter ≥10mm).

(3) Reduced PV Panel Output

- Troubleshooting Steps:

-

- Check surface cleanliness (efficiency drops 15% if dust coverage >20%), schedule cleaning;

- Use infrared thermal imager (e.g., FLIR E60); if hot spots present (local temperature >70°C), possible cell micro-cracks, replace panel;

- Check junction box diodes; replace if shorted (recommended: Schottky diode, forward voltage drop ≤0.5V).

5. Case Studies: Solar Lighting in North American Gas Stations

5.1 Case 1: Los Angeles, California Gas Station Retrofit

- Background: 2023 retrofit of a Shell station replacing traditional metal halide with solar explosion-proof lighting. Area: 5000 m², including 6 fuel dispensers, 2 tank areas, 1 walkway.

-

System Configuration:

- Luminaires: 15 UL 844 certified explosion-proof LED (15W, 3000K warm white, IP66);

- PV System: 2.4 kW array (12x 200W monocrystalline panels, 35° tilt, south-facing);

- Energy Storage: 5 kWh LiFePO4 battery (UL 9540), with MPPT controller (98% efficiency).

-

Performance Data:

- Annual Generation: 3600 kWh, exceeding lighting demand (1800 kWh/year), excess fed back to station grid;

- Energy Savings: $2,160 annual savings (CA commercial rate $0.30/kWh), 4.8-year payback;

- Safety Certification: Passed NFPA 30 and OSHA 1910.106 inspection, zero safety incidents.

5.2 Case 2: Houston, Texas Gas Station Lightning Protection Upgrade

- Problem: After Hurricane Ida (2022), lightning strike damaged solar lighting system: 3 luminaires and 1 controller failed.

-

Solution:

- SPD Upgrade: Installed DEHNguard DG M TT 20 kA SPD (response time 25 ns);

- Grounding Optimization: Expanded grounding grid (added 6x 2.5m electrodes, 5m spacing), used reducing agent to lower resistance from 8Ω to 4Ω;

- PV Panel Protection: Added lightning rods to module frames (protection angle ≤45°), down conductor 50 mm² copper cable.

- Result: System experienced 3 lightning strikes during 2023 rainy season (June-Sept) with no damage, luminaires operational.

6. Compliance Tools and Resources

6.1 Standard Reference Tools

- NFPA 30 Online Database: https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=30

- UL Certification Verification: https://iq.ul.com/ (enter product model to verify explosion-proof rating and certification status)

- OSHA Hazardous Area Classification Guide: https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.106

6.2 Design Assistance Tools

- NREL PVWatts Calculator: https://pvwatts.nrel.gov/ (estimate PV generation by inputting location, component parameters);

- IES Lighting Design Software: Dialux Evo (simulate illuminance distribution, generate IES RP-18 compliant lighting plans);

- Explosion-Proof Spacing Calculator: NFPA 30 Hazardous Area Calculator (automatically calculates safe distances from hazardous areas).

Conclusion

Safety standards for gas station solar lighting represent the integration of technical specifications and practical application. Strict adherence to NFPA, OSHA, UL, and other authoritative standards is essential, with risk management throughout system design, installation, and maintenance. By selecting explosion-proof certified components, optimizing grounding and lightning protection systems, and implementing regular maintenance schedules, gas stations can achieve 30%-50% energy savings while ensuring safety.

North American regulatory oversight of gas station safety is increasingly stringent (e.g., California requiring 100% explosion-proof renewable energy lighting for new stations from 2025). Mastering the safety standards and technical solutions outlined here will help businesses seize market opportunities and build a professional reputation while maintaining compliance.

References:

- National Fire Protection Association (NFPA), NFPA 30: Flammable and Combustible Liquids Code, 2023 Edition.

- Occupational Safety and Health Administration (OSHA), 29 CFR 1910.106: Flammable Liquids, 2022.

- Underwriters Laboratories (UL), UL 844: Standard for Luminaires for Use in Hazardous (Classified) Locations, 7th Edition.

- Illuminating Engineering Society (IES), *RP-18: Recommended Practice for Lighting for Roadway and Area Lighting*, 2018.

- National Renewable Energy Laboratory (NREL), Solar Resource Data for the United States, 2023.