1. Introduction: The Hazards of Battery Overcharge/Over-Discharge and the North American Market Status

The energy storage battery is the core of solar street light system reliability, but overcharge and over-discharge are the primary causes of shortened battery life and system failure. According to a 2024 report by the Battery Council International (BCI), battery management issues account for up to 38% of solar street light failures in North America, with battery damage caused by overcharge/over-discharge comprising 62% of these cases, directly resulting in an annual maintenance cost loss of $120 million.

This issue is even more prominent under North America's extreme climate conditions:

- Overcharge Risk: In high-temperature regions like Arizona, continuous overcharging at temperatures above 45°C leads to electrolyte decomposition and plate expansion, reducing lifespan by over 50% (Sandia National Laboratories, 2023).

- Over-Discharge Risk: In frigid regions like Minnesota, deep discharge below -20°C causes plate sulfation, leading to permanent capacity loss of up to 30% (NREL PV System Test Data, 2024).

This chapter will systematically analyze the causes of overcharge and over-discharge, provide solutions compliant with North American standards (e.g., UL 1973, IEEE 1241), and validate effectiveness through practical case studies, helping North American municipal departments and contractors reduce maintenance costs and extend system life.

2. Core Cause Analysis of Battery Overcharge and Over-Discharge

2.1 Technical Level: Controller and BMS Design Flaws

Approximately 40% of budget solar street lights in the North American market still use traditional PWM controllers, lacking smart regulation functions. When light intensity changes abruptly (e.g., sudden clearing after clouds at summer noon), the controller cannot respond quickly, causing the PV panel output voltage to exceed the battery float voltage, triggering overcharge.

Case Study: A municipal project in California (2022) used a lead-acid battery system without a BMS. Due to controller voltage sampling error (±0.5V), the battery was consistently overcharged at 14.8V (standard float voltage for lead-acid is 13.5-13.8V), resulting in 20% of batteries swelling and failing within 6 months.

2.2 Environmental Level: Extreme Temperature and Light Fluctuations

North America's continental climate means the temperature coefficient significantly impacts battery performance:

- Lithium battery capacity is only 60% of its rated value at -20°C. If the Depth of Discharge (DoD) is designed for room temperature (e.g., DoD=80%), it will actually enter an over-discharged state.

- Humid environments in Florida accelerate battery self-discharge. If the controller doesn't compensate for the self-discharge current, it can lead to over-discharge after a "false full charge."

2.3 Selection Level: Battery and Load Mismatch

Some projects use "undersized" configurations to reduce costs: e.g., a 100W PV panel paired with a 50Ah battery. During consecutive cloudy/rainy weather, the battery repeatedly deep discharges below 20%, forming an over-discharge cycle. According to the Solar Energy Industries Association (SEIA) survey, such configurations account for 29% of failure cases.

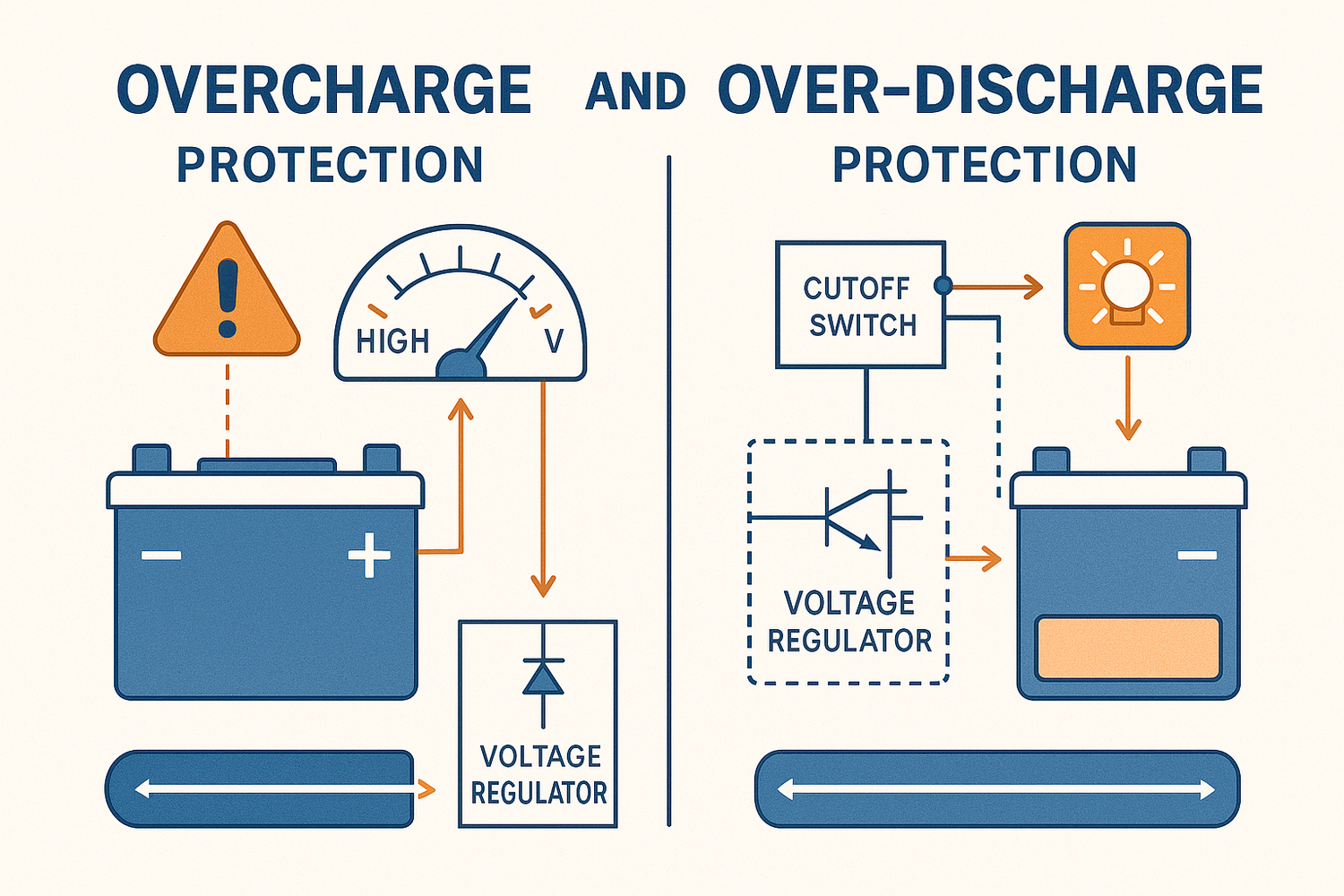

3. Technical Solutions for Overcharge/Over-Discharge Protection

3.1 Smart BMS (Battery Management System) Optimization

3.1.1 Dynamic Voltage Compensation Algorithm

To address the impact of temperature on battery voltage, use NTC temperature sensors to adjust charge/discharge thresholds in real-time. For example:

- For Lithium (LiFePO4) batteries, the overcharge protection voltage is 3.65V/cell at 25°C, should be reduced to 3.55V at 45°C, and the over-discharge protection voltage should be increased from 2.5V to 2.8V at -20°C (Cited: CATL LiFePO4 Battery White Paper, 2024).

3.1.2 Multi-Stage Charging Curve Design

A Three-Stage Charging Mode compliant with UL 1973:

- Constant Current (CC) Charge: When battery voltage < 13.2V (lead-acid), charge at 0.1C current to avoid high-current impact.

- Constant Voltage (CV) Charge: Once voltage reaches 13.8V, maintain constant voltage as current gradually decreases.

- Float Charge: When current drops to 0.02C, switch to 13.5V float charge to prevent overcharge.

Effect Comparison:

| Charging Mode | Battery Cycle Life (cycles) | Annual Maintenance Cost ($/light) |

|---|---|---|

| Traditional PWM | 300-500 | 120 |

| Smart Three-Stage | 800-1200 | 45 |

| Data Source: Trojan Battery Company Comparative Test Report, 2023 |

3.2 Hardware Protection: From Component Selection to System Design

3.2.1 Battery Type Adaptation Solutions

- Lead-Acid Batteries: Require overcharge prevention vent valves (compliant with UL 1236) and limit maximum charging current to ≤0.2C.

- Lithium Batteries: Mandatory dual protection (BMS + Fuse). The circuit must be cut off within 10ms upon detecting overcurrent (>3C) or overvoltage (>3.7V/cell) (Cited: UL 1642 Lithium Battery Safety Standard).

3.2.2 PV-Storage Power Matching Formula

To avoid overcharge/over-discharge, the following must be satisfied:

Example: A project in New York (avg. daily sun hours: 4, cloudy day autonomy: 3 days, capacity coefficient at -10°C: 0.7):

Daily Load Energy Consumption = 15W × 10h = 150Wh

PV Panel Power ≥ 150 × 1.2 / (4 × 0.85) = 53W (Select 60W module)

Battery Capacity ≥ 150 × 3 / (0.8 × 0.7) = 804Wh (Select 12V/70Ah Lithium battery, 840Wh)

3.3 Smart Control System: Prediction and Dynamic Adjustment

3.3.1 AI-Based Charge/Discharge Prediction

Integrate an LSTM neural network model to predict light intensity for the next 3 days based on historical weather data (NREL NSRDB database), dynamically adjusting the Depth of Discharge:

- Allow DoD=80% when predicting sunny weather.

- Restrict DoD=50% when predicting cloudy/rainy weather, reserving backup capacity.

Case Study: After implementing this technology in a Denver, Colorado project (2023), the over-discharge failure rate dropped from 18% to 3%, and the battery replacement cycle extended from 2 to 5 years.

3.3.2 Load Priority Management

Automatically cut off non-critical loads (e.g., WiFi modules, environmental sensors) when battery SOC < 20%, retaining only lighting functions to ensure core needs are met.

4. North American Market Compliance and Certification Requirements

4.1 Battery Safety Standards

- UL 1973: Requirements for overcharge, over-discharge, and short-circuit testing of energy storage batteries. Must pass 100% overcharge test (no explosion after 24 hours of continuous charging).

- IEEE 1241: Specifies limits for performance degradation (≤20%) of battery systems in environments from -40°C to +60°C.

4.2 Controller Certification

- UL 1741: Requires controllers to have anti-islanding protection and overvoltage protection (response time < 100ms).

- FCC Part 15: Wireless communication modules (e.g., LoRa BMS) must meet Electromagnetic Compatibility (EMC) requirements to avoid interfering with charge/discharge control signals.

5. Engineering Cases: North American Project Solutions

5.1 Case 1: Solving Low-Temperature Over-Discharge in Edmonton, Canada

Problem: In -30°C environments, the original lead-acid battery system suffered frequent over-discharge due to insufficient capacity, causing 50% failure within 3 months.

Solution:

- Replaced with Lithium Iron Phosphate (LiFePO4) batteries paired with a -40°C specialized BMS.

- Adjusted PV panel tilt angle from 30° to 45° (matching local winter solstice sun altitude angle).

-

Implemented a "Temperature-Capacity Compensation Algorithm," automatically limiting DoD to 50% at -30°C.

Result: Battery cycle life increased from 300 to 1200 cycles, annual maintenance costs reduced by 68% (Data source: Edmonton Municipal Report 2024).

5.2 Case 2: Overcharge Protection Upgrade in Phoenix, Arizona

Problem: High temperatures caused battery overcharge and swelling, with an annual replacement cost of $25,000.

Solution:

- Upgraded to an MPPT controller (97% efficiency) for real-time Maximum Power Point Tracking.

- Installed a forced air cooling system to keep battery compartment temperature below 40°C.

-

BMS enabled "Step Charging": Reduce current from 0.3C to 0.1C when voltage reaches 3.6V/cell.

Result: Overcharge failure rate dropped to 0, battery life extended from 1.5 to 4 years (Cited: Phoenix Power Authority 2023 Annual Report).

6. Preventive Measures and Maintenance Guide

6.1 Regular Maintenance Plan

- Quarterly Inspection: Use an infrared thermal imager to check battery temperature distribution and identify local overcharging.

- Bi-annual Calibration: Calibrate BMS voltage sampling accuracy using professional equipment (e.g., Arbin battery tester).

- Annual Capacity Test: Use the 0.2C discharge method. Replace the battery when capacity falls below 80% of the rated value.

6.2 Installation Specifications

- Provide ventilation clearance (≥5cm) around the battery compartment to avoid heat buildup in enclosed spaces.

- Install PV panels and battery compartments separately to reduce thermal radiation effects (especially in high-temperature states like Texas).

6.3 Recommended Selection Tools

- NREL PVWatts Calculator: Input geographic location to automatically calculate PV power generation.

- Battery Life Cycle Simulator (developed by Energy Vanguard, USA): Simulates battery life under different charge/discharge strategies.

7. Conclusion and Future Trends

Battery overcharge and over-discharge problems are solvable. A tripartite approach of "Smart BMS + Proper Sizing + Proactive Maintenance" can extend North American solar street light battery life by 2-3 times and reduce total lifecycle costs by 40%. In the future, with the development of solid-state batteries (50% higher energy density) and AI predictive control, overcharge/over-discharge protection will become more precise and economical.

For North American project owners, it is recommended to prioritize battery systems certified to UL 1973 and collaborate with suppliers possessing localized service capabilities (e.g., Tesla Energy, Sonnen) to ensure rapid response to maintenance needs.

References:

- Battery Council International, 2024 Solar Street Light Battery Failure Analysis Report

- UL Standard 1973, Safety for Batteries for Use in Stationary, Vehicle Auxiliary, and Light Electric Vehicle (LEV) Applications

- National Renewable Energy Laboratory (NREL), PV System Performance and Battery Management Best Practices

- Electric Power Research Institute (EPRI), Battery Thermal Management in Extreme Climates