1. The Critical Impact of Unstable Foundations

Foundations are the "root system" of solar street lights, directly determining system safety, functionality, and lifespan. According to NALSA's 2024 Failure Mode Analysis Report, foundation instability causes 23% of field failures—surpassing controller issues (18%) and battery problems (15%). In extreme cases, foundation failure can lead to pole collapse, averaging $2,800 per repair and up to 6 weeks of service disruption (APWA 2023 Annual Report).

Key Risks:

- Structural Hazards: Pole tilting/collapse risks injury and property damage (especially in hurricane-prone Southeast)

- Performance Loss: 3.2% annual energy reduction per 5° PV misalignment (NREL field data)

- Equipment Damage: Settlement strains cables, breaking waterproof seals and internal wiring

- Cost Surge: Foundation repairs cost 40% more than initial installation (BLS data)

North America's Geographic Challenges:

- Northeast: Frost heave lifts foundations 6-10"

- Southwest: Sand liquefaction causes lateral displacement

- Northwest: Soil erosion from heavy rainfall

- Coastal Regions: Salt corrosion weakens metal anchors

2. Root Cause Diagnosis

2.1 Soil Analysis: Engineering Challenges by Type

Table 1: North American Soil Properties

| Soil Type | Regions | Risks | Key Issues | Bearing Capacity |

|---|---|---|---|---|

| Clay | NE, Midwest | High (frost heave) | 12% shrinkage/swell cycles | 150-300 kPa |

| Sand | SW, Coasts | Medium-High | Liquefaction under vibration | 80-200 kPa |

| Silt | Mississippi Valley | Medium | Pore pressure from rainwater | 100-250 kPa |

| Peat | FL, Pacific NW | Extreme | 2" annual settlement | <50 kPa |

| Rocky | Appalachians, Rockies | Low | Anchor installation difficulty | >500 kPa |

Case: Chicago O’Hare Airport project (2022)

Shallow foundations in clay caused 12/53 lights to tilt 3-7° during winter ($42k repair).

2.2 Design Flaws

- Undersized Wind Loads: Houston lost 17 lights during Hurricane Nicholas (2021) after designing for 110mph vs required 130mph (TxDOT).

- Foundation Selection Errors:

Table 2: Foundation Type Guide

| Type | Best For | Avoid In | Cost ($/light) |

|---|---|---|---|

| Concrete Spread | Medium soils (<40ft poles) | High water table | $150-250 |

| Helical Pile | Sand/clay/frost zones | Bedrock | $200-350 |

| Ballast Block | Historic districts (no-dig) | High-wind areas | $300-500 |

| Rock Anchor | Mountainous terrain | Shallow topsoil | $250-400 |

2.3 Construction Errors (68% of failures per AGC)

- Inadequate excavation depth (e.g., 0.8m vs MN's 1.2m frost depth)

- Poor compaction (<95% Proctor density)

- Concrete defects: High water-cement ratio, insufficient curing

2.4 Environmental Stressors

- Frost Heave: 200kPa uplift forces in <0°C regions (USACE: 4-6" settlement over 5 years)

- Wet-Dry Cycles: Clay fissures in prairie states (e.g., Kansas)

- Bioerosion: 42% termite damage to wood foundations in 3 years (UF Entomology)

3. End-to-End Solutions

3.1 Site Investigation (ASTM D2487)

- Soil classification & bearing tests (DCP/SPT at 0.5/1.0/1.5m depths)

- Water table measurement (50cm below foundation base)

- Frost depth verification (USGS maps + 30cm margin)

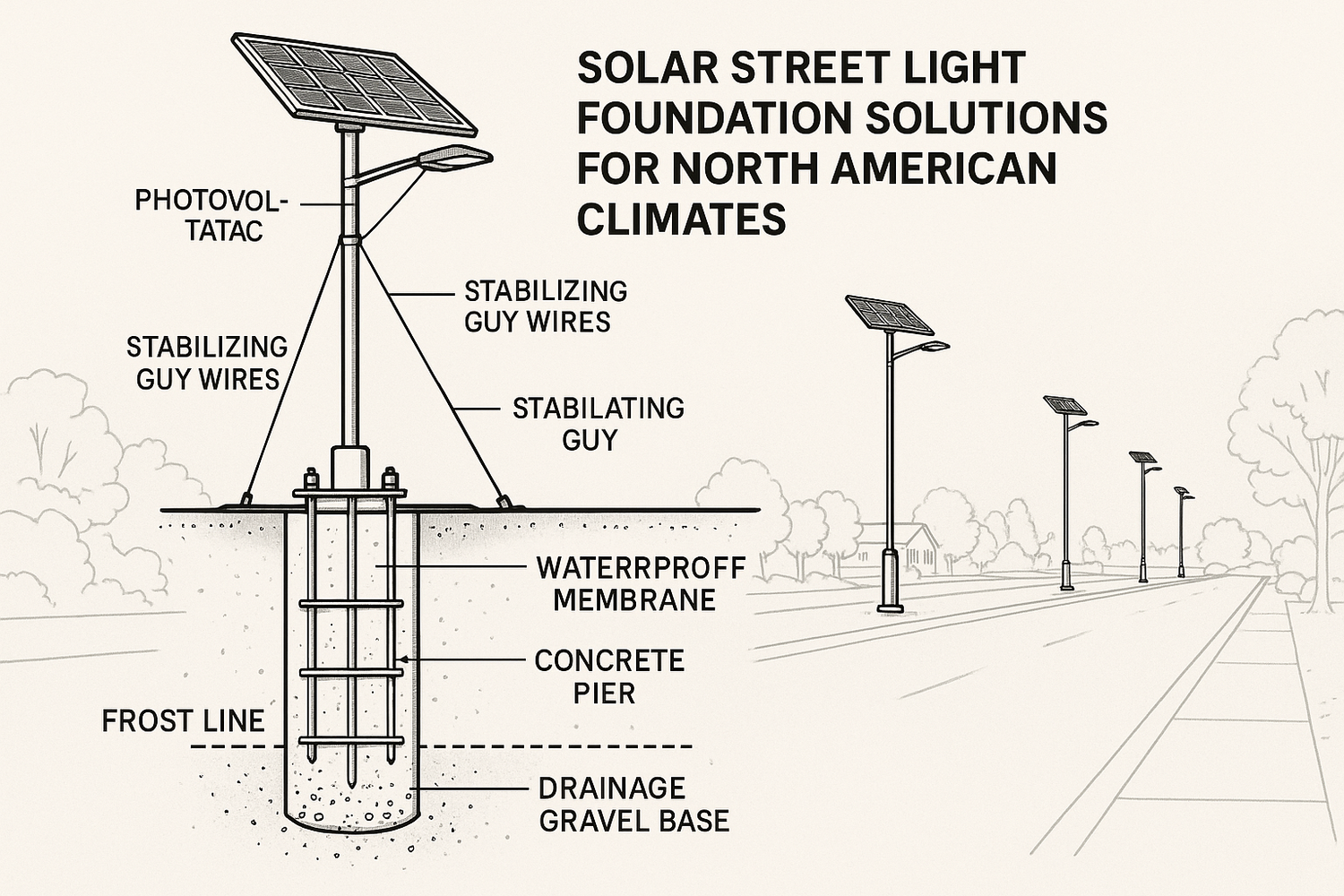

3.2 Climate-Adaptive Designs

-

Wind Load Compliance: ASCE 7-22 Chapter 26 calculations

- NYC (120mph): 9,200 lb-ft overturning resistance for 40ft pole

- LA (110mph): 8,000 lb-ft for same pole

-

Frost Heave Mitigation:

- Phase Change Material (PCM)-filled piles

- 2" XPS insulation wrap

- Helical plates (2× shaft diameter)

3.3 Construction Best Practices

- *Concrete Foundations (ASTM C39/C150):*

- C30 mix (≥4,350 psi) with 1/2" rebar @ 6" spacing

- 4" gravel base (95% compaction)

- 7-day moist curing

-

Helical Piles:

- 2000 N·m hydraulic drive

- ≤1° vertical tolerance

- Proof testing to 120% design load (ASTM D3689)

3.4 Innovative Technologies

- Geopolymer Foundations: 50MPa strength, 70% lower CO2 (San Diego Port Project)

- Self-Healing Concrete: 80% crack repair via Bacillus pasteurii microbes (CU Boulder)

4. Quality Assurance

4.1 Inspection Checklist

| Item | Standard | Tolerance |

|---|---|---|

| Excavation Depth | ≥ Design + frost margin | +2" |

| Compaction | ≥95% Proctor | ±2% |

| Concrete Slump | 6-8" (ASTM C143) | ±0.75" |

| Anchor Bolt Layout | ±0.2" |

4.2 IoT Monitoring

- Embedded tilt sensors (e.g., Sensorex DTI-100)

- LoRaWAN alerts at >1° tilt (Phoenix project prevented 7 collapses in 2023)

5. Case Studies

5.1 Boston Historic District (Clay + High Water Table)

- Solution: Helical piles + jet grouting cutoff wall

- Result: 0.12" settlement over 2 years

5.2 Phoenix Desert (Sand + 140°F Surface Temp)

- Solution: Geogrid-reinforced concrete + polypropylene fibers

- Result: 5,000 psi concrete with zero cracks after 3 years

6. Maintenance Protocol

- Quarterly: Clear drainage paths

- Biannual: Survey settlement with total station

- Annual: Re-torque anchor bolts (35-50 N·m)

- Emergency: Micropile underpinning for >1° tilt (60% cost savings in NYC)

7. Compliance Framework

- Structural: ASCE 7-22

- Geotechnical: ASTM D698

-

Regional:

- Florida: 1.8x wind load safety factor

- California: UBC 1997 seismic design

8. Key Recommendations

- Mandatory soil testing before foundation design

- 1.5x safety factor for critical infrastructure

- Real-time IoT foundation monitoring in high-risk zones

- Strict adherence to ASCE/ASTM standards

"Ignoring foundation design is like building on quicksand—eventually, the light will fall."

– NALSA Technical Committee, 2024

Sources Cited:

-

American Society of Civil Engineers (ASCE). (2022). ASCE 7-22: Minimum Design Loads.

-

National Renewable Energy Laboratory (NREL). (2023). Solar Street Lighting Installation Best Practices.

-

North American Solar Lighting Association (NALSA). (2024). Foundation Design Guide.

-

U.S. Department of Agriculture (USDA). (2023). Soil Survey Manual.

- Federal Highway Administration (FHWA). (2021). Geotechnical Engineering Circular No. 5.