1. Introduction: Impact of LED Degradation on Solar Lighting Systems

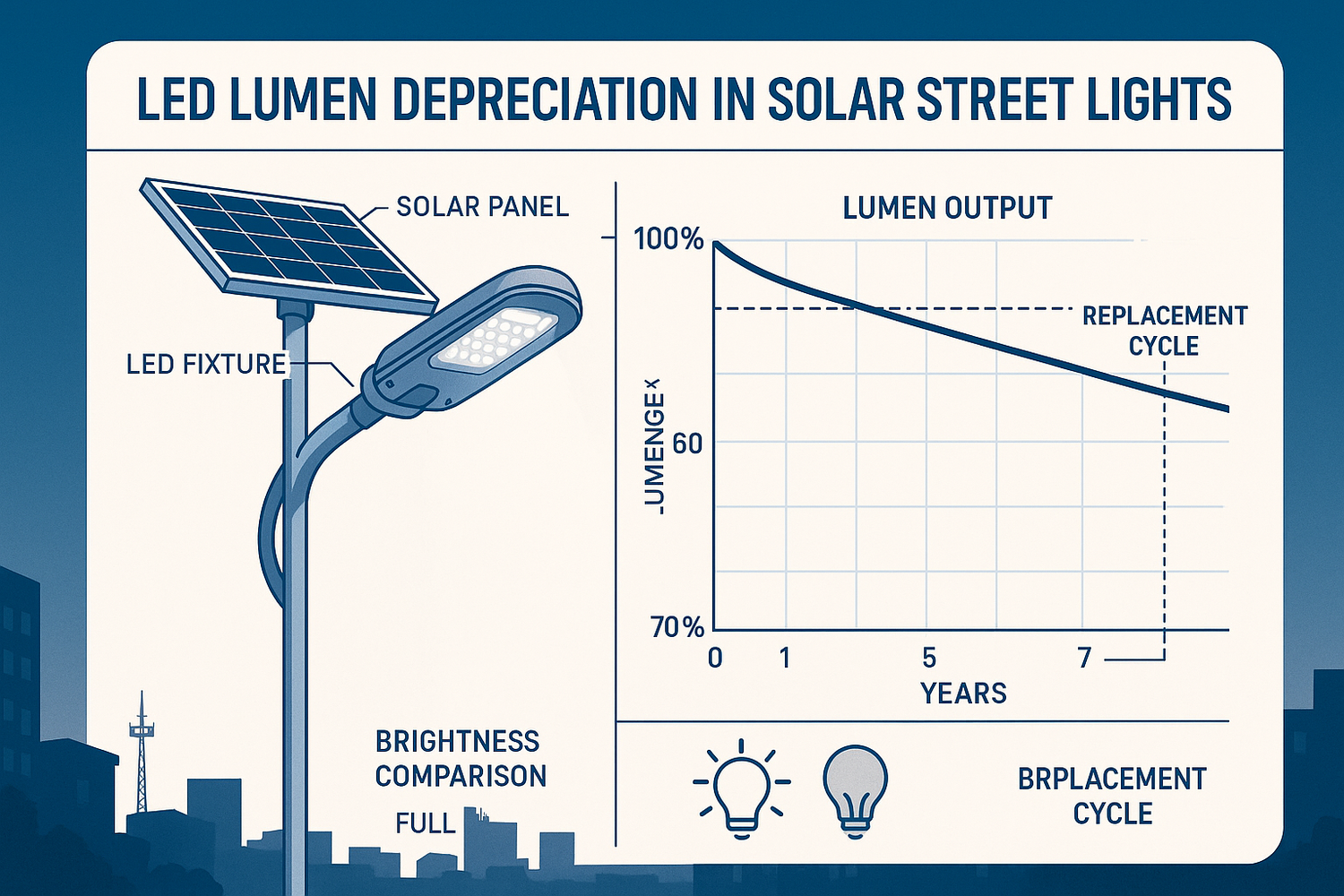

As the core component of solar street lights, LED (Light Emitting Diode) performance stability directly determines lighting system reliability and lifecycle economics. In North American solar street lighting applications, LED lumen depreciation accounts for approximately 34% of post-installation maintenance issues (Source: ALI 2024 Outdoor LED Reliability Report). Industry standards define the L70 lifespan as the point when luminous flux decays to 70% of initial output – beyond which pavement illuminance drops, safety risks increase, and system efficiency declines.

North America-Specific Challenges:

- Climate Diversity: Temperature swings from Alaska's extreme cold (-40°C) to Arizona's heat (+50°C) accelerate LED degradation.

- Stringent Lighting Standards: Municipal road lighting must comply with IESNA RP-8 (e.g., ≥20 lux illuminance for arterial roads).

- High Maintenance Costs: Labor rates averaging $85-120/hour make frequent replacements economically prohibitive.

This section systematically analyzes LED degradation mechanisms, influencing factors, assessment methods, and replacement strategies – providing actionable solutions aligned with North American climates and standards to optimize maintenance and reduce operational costs.

2. Core Mechanisms and Classification of LED Lumen Depreciation

LED lumen depreciation refers to irreversible luminous flux reduction over time. Per NEMA SSL 4 standards, it is categorized as:

2.1 Normal Depreciation (Predictable Linear Degradation)

Governed by Arrhenius aging model, accounting for >75% of failures:

-

Chip-Level Mechanisms:

- Quantum efficiency decline: GaN-based MQW active layer degradation under current stress. Cree data shows 3× faster decay at 85°C vs. 25°C junction temperature (Tj).

- Reduced light extraction efficiency: Surface roughening layer atomic migration increases reflectivity by 5-8% (NREL 2022).

-

Package-Level Mechanisms:

- Phosphor aging: YAG:Ce³⁺ quantum yield decline at >100°C (Philips Lumileds 2023: 30k hrs @ 85°C/85%RH vs. 60k hrs @ 55°C/60%RH).

- Encapsulant yellowing: Silicone/EPOXY carbonyl formation reduces transmittance to 70%, causing ~25% flux loss (ASTM D1148).

2.2 Abnormal Depreciation (Sudden Nonlinear Failure)

Caused by manufacturing defects or extreme environmental stress (<10k hours, >50% flux drop):

-

Manufacturing Defects:

- Bond wire detachment (<20gf ball strength per IPC-A-610).

- Thermal path failures: Contact thermal resistance >0.5°C/W causes localized overheating (DOE 2023 case: 40% decay in 12 months).

-

Environmental Stressors:

- Voltage surges: IEEE C62.41.2 requires 4kV line-ground surge protection.

- Salt corrosion: 15% accelerated decay after 500hr salt fog exposure (ASTM B117).

3. Key Environmental Factors in North American Climates

3.1 Temperature Effects

Tj increase of 10°C reduces L70 life by ~50% (Arrhenius model):

-

Southwest US (Phoenix, AZ):

Tj reaches 95-110°C. Unoptimized LEDs: 25k hr L70 vs. heat pipe designs: 55k hr (ASU 2024).

Solution: Low-Tj chips, aluminum PCB (k>2W/m·K), active cooling. -

Northern US (Anchorage, AK):

Thermal shock (-40°C to 80°C) causes encapsulant cracking. Standard silicones show 18% decay vs. 5% for fluorinated composites after 100 cycles (3M 2023).

Solution: Low-Tg silicones (e.g., Dow Corning SE 4450), PTC heaters.

3.2 Humidity & Precipitation

-

Southeast (Miami, FL):

85°C/85%RH causes encapsulant swelling and phosphor agglomeration. IP66-sealed LEDs show only 8% decay vs. 22% for unsealed units (UL 2023).

Solution: IP66/67 sealing, hydrophobic nano-coatings (contact angle >110°). -

Northeast (Boston, MA):

Snow accumulation increases Tj by 15-20°C. Ice melt causes short circuits (ASCE 2024 case: 15% decay in 3 months).

Solution: 15° tilt installation, thermal derating at Tj>110°C.

3.3 Current Stress

-

10% current ripple accelerates phosphor aging (ENERGY STAR requires <10% ripple). Houston testing showed 23% faster decay at 20% ripple vs. 5% (TI 2023).

-

Solar-induced current fluctuations require MPPT controllers + constant-current drivers (e.g., TI TPS6116x) maintaining ±5% current stability.

4. LED Degradation Assessment: Standards & Field Tools

4.1 Laboratory Testing (Product Selection)

- *IES LM-80:* 6,000-hr testing at 55°C/85°C/Tj(max). Mandatory for GSA Schedule 84 procurement.

- *TM-21 Prediction:* Extrapolates L70 life from LM-80 data (e.g., 92% @ 6k hrs → 52k hr L70).

4.2 Field Assessment (In-Service Systems)

- Illuminance Meter: Measure pavement lux vs. baseline. Replace when >30% decay (e.g., <14 lux from 20 lux initial).

- Spectrometer: Detect chromaticity shift (Δu'v'>0.007 indicates severe decay per ENERGY STAR).

- Thermal Imaging: Identify hotspots indicating thermal path failure (>15°C delta between adjacent LEDs).

5. Replacement Cycle Determination

5.1 Technical Lifespan by Climate Zone

| Climate Zone | Representative City | Avg. Temp | L70 Life | Replacement Cycle |

|---|---|---|---|---|

| Humid Subtropical | Miami, FL | 25-30°C | 60k hrs | 5-6 years |

| Hot Arid | Phoenix, AZ | 30-35°C | 55k hrs | 4.5-5.5 years |

| Temperate | Chicago, IL | 10-20°C | 70k hrs | 6-7 years |

| Cold | Minneapolis, MN | -10-15°C | 75k hrs | 6.5-7.5 years |

| Source: NREL 2024 North American LED Lifespan Map |

5.2 Economic Optimization (LCC Model)

LCC = Initial Cost + ∑(Annual Maintenance) + Replacement Cost × (System Life / Replacement Cycle)

Case Study: 50W LED ($120 initial, $200 replacement, 50k hr L70)

- 5-year cycle: $920

- 6-year cycle: $787 (optimal)

- 7-year cycle: $800 + compliance risk

5.3 Regulatory Requirements

- FHWA mandates ≥20 lux (arterial) / ≥10 lux (local roads).

- California Title 24 requires replacement when efficacy drops below 100 lm/W.

6. Life Extension Strategies (North American Case Studies)

6.1 Thermal Management: Los Angeles Municipal Project (2022)

Solution: Copper heat pipes + graphene TIM + honeycomb housing → Tj reduced from 95°C to 65°C, L70 extended to 62k hrs (55% lower maintenance costs).

6.2 Smart Dimming: Toronto Smart City Project (2023)

Solution: Radar motion sensing + 30% standby dimming → 40% current reduction, 25°C lower Tj, 60% lifespan extension.

6.3 Preventive Maintenance: Austin, TX Program

Solution: Biannual cleaning, thermal path inspection, driver calibration → 2-year lifespan extension at $30/unit (22% LCC reduction).

7. North American Case Studies: Replacement Cycles

7.1 Phoenix Highway Project (Hot Arid)

After 5 years: 28% flux decay, 18 lux illuminance → Replaced with thermal-optimized LEDs targeting 7-year cycle.

7.2 NYC Commercial District (Temperate)

Smart dimming (50% power after 23:00) enabled 7-year cycle despite 3000K CCT requirement.

7.3 Alaska Oil Field Lighting (Cold)

Low-Tg encapsulants + heater modules achieved 9% decay at Year 4 → Projected 10-year cycle despite -40°C conditions.

8. Actionable Recommendations

For Municipal Authorities:

- Require LM-80/TM-21 reports (L70>60k hrs) in procurement

- Implement 5-year comprehensive testing + annual sampling

- Budget for 5-7 year replacement cycles

For Contractors:

- Climate-specific thermal design (heat pipes in SW, cold-rated encapsulants in North)

- Install SPDs and ±5% constant-current drivers

- Offer predictive maintenance via remote Tj/lumen monitoring

For Property Managers:

- Phased replacement (20% biennially)

- Couple LED replacement with solar system upgrades

- Conduct annual illuminance checks for OSHA/NFPA compliance

Source:

1. Illuminating Engineering Society (IES). LM-80-20, “Approved Method for Measuring Lumen Maintenance of LED Light Sources”.

2. Department of Energy (DOE). “Solid-State Lighting Technology Fact Sheet”. 2024.

3. National Renewable Energy Laboratory (NREL). “LED Reliability in Outdoor Solar Lighting Systems”. 2023.

4. ENERGY STAR®. “Program Requirements for Luminaires”. Version 2.1, 2023.

5. American Society for Testing and Materials (ASTM). B117-21, “Standard Practice for Operating Salt Spray (Fog) Apparatus”.

6. Los Angeles Department of Transportation. “2024 Street Lighting Maintenance Report”.

7. Cree Inc. “XLamp XP-G3 LED Reliability Data”. 2023.

8. Philips Lighting. “LUXEON LED Lifetime Prediction Methodology”. 2022.