Imagine you need to upgrade your warehouse lighting in 2025. You want to cut energy costs, boost safety, and prepare for future changes. Start by looking at your warehouse’s ceiling height, layout, and work zones. You must balance performance, cost, and long-term value when choosing high bay led lights. Use lighting calculation tools to match fixtures to your space and needs.

Key Takeaways

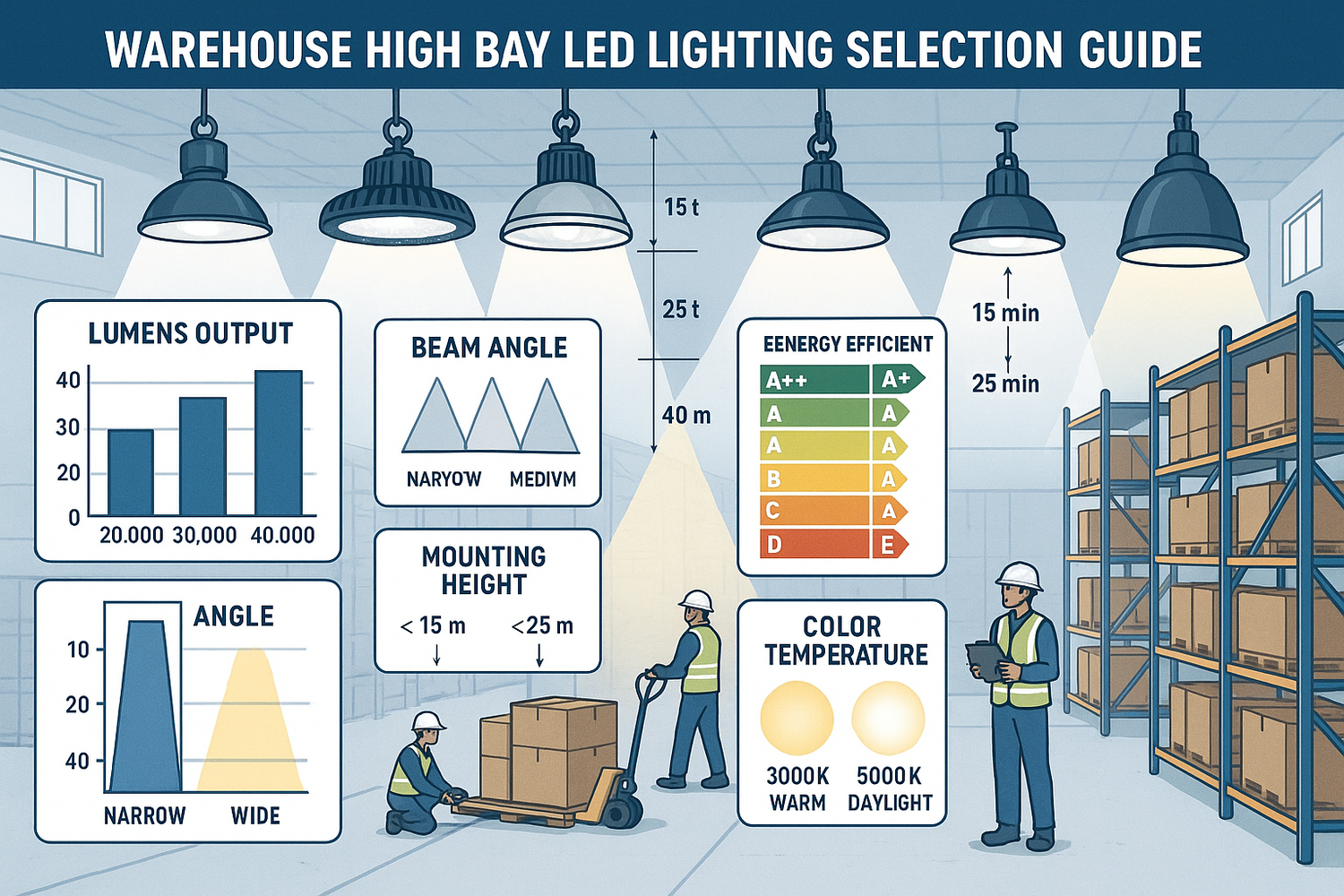

- Match high bay LED lights to your warehouse ceiling height for proper brightness and efficiency.

- Plan your lighting layout carefully to cover aisles, open areas, and task zones without dark spots.

- Choose brightness levels based on activity type, using more lumens for detailed tasks and less for general storage.

- Select durable fixtures with good environmental protection and certifications for long-lasting performance.

- Use energy-efficient LED lights with high lumens per watt to save on electricity costs.

- Consider smart controls like sensors and scheduling to reduce energy waste and improve lighting flexibility.

- Pick fixture styles and beam angles that fit your warehouse layout and lighting needs.

- Plan for future upgrades and expansions by choosing modular, adjustable lighting systems.

Warehouse Lighting Needs

Ceiling Height

Ceiling height plays a major role in your warehouse lighting plan. You must match the right fixture to your ceiling height to achieve proper brightness and efficiency. High bay LED lights work best for spaces with ceilings between 20 and 45 feet. If your warehouse has higher ceilings, you need fixtures with higher lumen output to deliver enough light to the floor. Lower ceilings benefit from recessed or surface-mounted lighting solutions. These options help you avoid glare and create even light distribution.

Tip: Always check the mounting height before you select your fixtures. The mounting height affects how many lights you need and how bright each one should be.

You should also consider fixture orientation and adjustability. Adjustable fixtures help you minimize shadows and improve visual comfort in high ceiling environments. For best results, space your fixtures about 1 to 1.5 times the mounting height apart. This spacing ensures uniform illumination and supports safety and productivity in large warehouses.

Layout

The layout of your warehouse shapes your lighting solutions. Start by mapping out aisles, storage racks, open areas, and loading docks. Each area may need a different lighting approach. For example, narrow aisles require focused lighting to reduce shadows, while open spaces need wide coverage for even brightness.

Use lighting calculation tools to plan fixture placement and quantity. These tools help you visualize how light spreads across your warehouse. You can adjust fixture positions to avoid dark spots and overlap. A well-planned layout reduces wasted energy and supports efficient warehouse lighting.

- Place fixtures along aisles for clear visibility.

- Use wide-beam fixtures in open areas.

- Add extra lights near loading docks and entrances.

Task Areas

Task areas need special attention in your warehouse lighting design. These zones include packing stations, inspection tables, and workbenches. Workers in these areas need higher light levels to perform detailed tasks safely and accurately.

Assess the wattage and lumen output required for each task area. Choose lighting solutions that provide focused, bright light without causing glare. You can use adjustable fixtures or add task lights to boost visibility where needed. Good lighting in task areas improves accuracy, reduces errors, and helps prevent accidents.

Note: Review your warehouse regularly to identify new task areas or changes in workflow. Update your lighting plan to match these changes and maintain optimal performance.

By considering ceiling height, layout, and task areas, you create a warehouse lighting system that supports safety, efficiency, and productivity. The right lighting solutions help you meet the demands of industrial lighting and commercial lighting in any warehouse setting.

Brightness

Brightness stands as a critical factor when you plan your warehouse lighting. You must ensure that every area receives enough light for safe and efficient work. The right brightness level depends on your warehouse size and the type of activities performed in each zone.

To determine how much light you need, start by calculating the total square footage of your warehouse. Multiply this number by the recommended lumens per square foot. Task areas, such as packing stations or inspection zones, require higher lumens per square foot than general storage spaces. For example, detailed work may need 30-50 lumens per square foot, while general areas often need 10-20 lumens per square foot.

Tip: Use lighting calculation tools to estimate the number of fixtures and their placement. These tools help you avoid dark spots and ensure consistent brightness throughout your warehouse.

When you select bulbs, focus on lumen output rather than wattage. Wattage measures energy consumption, not light produced. LED bulbs deliver more lumens per watt compared to traditional bulbs. This means you get brighter light while using less energy, which is especially important in large warehouses.

Consider these steps to assess brightness for your warehouse lighting:

- Measure the square footage of each area.

- Identify the activity level in each zone (general storage, detailed tasks, etc.).

- Multiply the area size by the recommended lumens per square foot for each activity.

- Choose LED fixtures with high lumens per watt to maximize energy efficiency.

- Check for energy efficiency ratings, such as Energy Star, to reduce operational costs.

- Calculate annual energy costs by factoring in wattage, usage hours, and electricity rates.

You should also think about future changes in your warehouse. If you plan to expand or add new task areas, select fixtures that allow easy upgrades. This approach helps you maintain optimal brightness and supports long-term value.

Proper brightness in warehouse lighting improves safety, reduces errors, and boosts productivity. You create a well-lit environment that supports every activity, from storage to detailed work. By following these steps, you make informed decisions that benefit your warehouse now and in the future.

High Bay LED Lights Features

Light Distribution

You want your warehouse to have even, reliable light in every corner. Light distribution describes how well your high bay lights spread illumination across your space. Good light distribution reduces shadows and dark spots, making your warehouse safer and more productive. When you select high bay led lights, look for fixtures that provide uniform coverage. Wide light distribution works best for open areas, while focused distribution suits aisles or specific work zones.

You can use lighting solutions with reflectors or diffusers to control how light spreads. Reflectors direct light downward, which helps in tall spaces. Diffusers soften the light, reducing glare and creating a comfortable environment. You should match the light distribution pattern to your warehouse layout and ceiling height. This approach ensures you get the best lighting performance for your needs.

Tip: Use led lighting solutions with adjustable reflectors if your warehouse layout changes often. This flexibility helps you adapt your lighting to new storage or workflow arrangements.

Beam Angle

Beam angle plays a key role in how your high bay lights cover your warehouse. The right beam angle ensures you get the most from your lighting solutions. A narrow beam angle creates a focused, intense light. This option works well for highlighting specific products or workstations. A wide beam angle spreads light over a larger area, which is ideal for general warehouse lighting.

- Narrow COB strips produce tight, focused beams. Use these when you need to spotlight products or details.

- Wider COB strips create broad, even coverage. Choose these for illuminating large surfaces in your warehouse.

- Wider strips offer better heat dissipation. They handle higher power and produce more light without overheating.

- Narrow strips have limited heat dissipation. They may need extra cooling, which can complicate installation and reduce efficiency.

- The width of the COB strip affects compatibility with channels and diffusers. This impacts both light uniformity and thermal management.

- For industrial lighting in warehouses, wider COB strips (10mm or more) are best. They maintain steady brightness and manage heat during long hours of operation.

You should always match the beam angle to your warehouse needs. Wide beam angles work well for open spaces, while narrow angles suit focused tasks. This choice helps you achieve energy efficient lighting and reduces wasted energy.

Durability

Durability matters when you invest in high bay led fixtures for your warehouse. You need lighting solutions that withstand tough conditions and last for years. High bay lights built with premium-grade components offer the best value. Look for rugged metal housings and acrylic lenses. These materials resist impacts and protect the internal parts.

You should also check for environmental ratings. Many high bay led lights are suitable for both dry and damp locations. This feature ensures your lighting performs well in different warehouse environments. Certifications like UL Listed, RoHS Compliant, and DLC Premium Listed guarantee safety and compliance.

Here is a table showing key durability features to look for in high bay lighting systems:

|

Durability Feature |

Description |

|---|---|

|

Housing Material |

Rugged metal housing designed to endure high-traffic, demanding environments |

|

Lens Material |

Acrylic lens built for durability in industrial settings |

|

Environmental Suitability |

Suitable for dry and damp locations |

|

Certifications |

UL Listed, RoHS Compliant, DLC Premium Listed (ensures safety and compliance) |

|

Lifespan |

L70 rated for over 50,000 hours of operation |

|

Warranty |

5 years warranty supporting long-term reliability |

|

Operational Benefits |

Engineered for low operational costs and long-term reliability |

You want high bay led lights that deliver long-term performance and low maintenance. Choose led lighting products with a lifespan of over 50,000 hours. This choice reduces replacement costs and downtime. Many energy-efficient products also come with a five-year warranty, giving you peace of mind.

Note: Durable high bay lights help you maintain consistent lighting performance and support your warehouse operations year after year.

Environmental Protection

You need high bay lights that can handle tough warehouse conditions. Dust, moisture, and temperature changes challenge your lighting system every day. When you choose high bay lights, check their environmental protection ratings. These ratings show how well your fixtures resist dust and water.

The most common rating is the IP (Ingress Protection) code. This code uses two numbers to describe how much protection your high bay lights offer. The first number shows dust resistance. The second number shows water resistance. You can use the table below to compare different IP ratings and decide which suits your warehouse best.

|

IP Rating |

Protection Level Description |

Suitability for Warehouse High Bay LED Lights |

|---|---|---|

|

IP65 |

Protects against dust ingress and low-pressure water jets from any direction |

Suitable for indoor/outdoor warehouses, especially with high humidity or washdown areas |

|

IP66 |

Dust-tight and protected against powerful water jets from any angle |

Ideal for harsher industrial or outdoor environments requiring high-pressure cleaning |

|

IP67 |

Dust-tight and can withstand temporary immersion in water up to 1 meter for 30 minutes |

Suitable for wet processing areas or flood-prone locations |

|

IP68 |

Dust-tight and can withstand continuous immersion in water under higher pressure |

Best for extreme environments like marine or underwater lighting installations |

You should select high bay lights with at least an IP65 rating for most warehouses. This rating keeps dust out and protects against water jets. If your warehouse faces frequent cleaning or high humidity, consider IP66 or higher. These ratings help your high bay lights last longer and reduce maintenance costs.

Look for fixtures with die-cast aluminum housings. These housings resist corrosion and support heat dissipation. Some high bay lights work at temperatures up to 65°C (149°F). This feature ensures reliable performance in hot environments. You can trust your led lighting solutions to keep working, even when conditions get tough.

Tip: Always check the IP rating before you buy high bay lights. The right rating protects your investment and keeps your warehouse safe.

Smart Controls

Smart controls help you get the most from your high bay lights. You can use networked lighting control systems to link your fixtures. These systems let you adjust brightness, set schedules, and monitor energy use. You save money and improve lighting quality.

You can also use photocell controls. These controls turn your high bay lights on or off based on natural light levels. When sunlight fills your warehouse, your lights dim or shut off automatically. This feature reduces energy waste and extends the life of your fixtures.

Here are some smart control options for high bay lights:

- Networked lighting control systems for centralized management

- Photocell controls for automatic adjustment based on daylight

- Scheduling features to match your warehouse operations

- Energy monitoring tools to track usage and savings

Smart controls make your warehouse lighting flexible and efficient. You can respond to changes in workflow or occupancy. You also support sustainability by lowering your energy consumption.

Note: Smart controls work best when you combine them with high bay lights designed for easy integration. Choose fixtures that support wireless or wired control systems.

Certifications

Certifications show that your high bay lights meet safety and performance standards. You should look for fixtures with UL Listed, RoHS Compliant, and DLC Premium Listed marks. These certifications prove your lights are safe, reliable, and energy efficient.

- UL Listed means your high bay lights pass strict safety tests.

- RoHS Compliant shows your fixtures do not contain hazardous materials.

- DLC Premium Listed confirms your lights meet high energy efficiency standards.

You can trust certified high bay lights to deliver consistent performance. These certifications also help you qualify for energy rebates and incentives. When you choose certified fixtures, you protect your warehouse and your budget.

Tip: Always check for certifications before you buy high bay lights. Certified products offer better quality and long-term value.

Adjustable Color Temperature

You can control the mood and function of your warehouse lighting with adjustable color temperature. This feature lets you change the color of the light from warm to cool. You get more flexibility for different tasks and times of day.

What is Color Temperature?

Color temperature measures the color of light in Kelvin (K). Lower numbers mean warmer, yellowish light. Higher numbers mean cooler, bluish light. Adjustable color temperature means you can set your high bay LED lights to the best color for your needs.

|

Color Temperature |

Appearance |

Best Use Cases |

|---|---|---|

|

3000K |

Warm White |

Break rooms, offices |

|

4000K |

Neutral White |

General warehouse, packing |

|

5000K |

Cool White |

Inspection, detailed work |

|

6500K |

Daylight |

High-precision, quality control |

Why Adjustable Color Temperature Matters

You can match the lighting to the activity in each area. For example, you may want cool white (5000K) in inspection zones to help workers see details. You may prefer neutral white (4000K) in general storage areas for comfort and visibility. Adjustable color temperature also helps reduce eye strain and fatigue.

Tip: Use cooler color temperatures for tasks that need focus and accuracy. Choose warmer tones for areas where workers relax or take breaks.

How to Use Adjustable Color Temperature

Many high bay LED lights come with a switch or remote control. You can set the color temperature during installation or change it later. Some smart lighting systems let you adjust color temperature with an app or control panel.

- Set cooler light (5000K–6500K) for quality control, sorting, or inspection.

- Use neutral light (4000K) for general warehouse operations.

- Switch to warmer light (3000K) in break rooms or offices.

Benefits for Your Warehouse

You improve worker comfort and productivity when you use the right color temperature. You also create a safer environment by reducing glare and shadows. Adjustable color temperature gives you the power to adapt your lighting as your warehouse changes.

Note: Always check if your high bay LED lights support adjustable color temperature before you buy. This feature adds value and flexibility to your lighting system.

High Bay Lights Selection

Fixture Style

You have several fixture styles to choose from when selecting high bay lights for your warehouse. Each style offers unique benefits for different spaces and ceiling heights. The two most popular options are:

- UFO High Bay Light: This style features a round, compact design. You can install UFO high bay lights in spaces with high ceilings. The shape allows for even light distribution and easy installation. Many warehouse managers prefer UFO high bay lights because they save space and provide strong illumination for tall areas.

- LED Linear High Bay Light: This style looks like a long, rectangular fixture. You can use linear high bay lights in aisles or areas with shelving. The shape helps direct light along the length of the space, making it ideal for warehouses with rows of racks.

UFO high bay lights stand out for high ceilings. Their compact design and powerful output make them a top choice for large, open warehouse spaces. You can rely on these high bay light fixtures to deliver consistent brightness and reduce shadows.

Tip: Match the fixture style to your warehouse layout. UFO high bay lights work best for open areas, while linear fixtures suit aisles and narrow spaces.

Lumen Output

Lumen output tells you how much visible light a fixture produces. You need to select high bay lights with the right lumen output for your warehouse size and ceiling height. If you choose lights that are too dim, you risk creating dark spots and reducing safety. If you pick lights that are too bright, you may waste energy and cause glare.

Follow these steps to determine the best lumen output:

- Measure the square footage of your warehouse.

- Decide the brightness level needed for each area. General storage needs fewer lumens than task zones.

- Multiply the area by the recommended lumens per square foot.

- Choose high bay led lights that meet or exceed this total.

Most high bay light fixtures for warehouses range from 10,000 to 40,000 lumens. Higher ceilings need fixtures with more lumens to ensure the light reaches the floor. You can use lighting calculation tools to help plan the number and placement of fixtures.

Energy Efficiency

Energy efficiency should guide your decision when selecting high bay lights. You want fixtures that deliver strong illumination while using less power. High bay led lights offer excellent energy efficiency compared to older lighting options. You can lower your electricity bills and reduce your carbon footprint by choosing energy efficient lighting.

Look for high bay light fixtures with high lumens per watt. This rating shows how much light you get for each unit of energy used. Many modern high bay lights also support smart controls, which help you save even more energy by adjusting brightness based on occupancy or daylight.

Note: Energy efficient lighting not only saves money but also supports sustainability goals in industrial lighting environments. You can upgrade your warehouse with led lighting that meets both your performance and efficiency needs.

Lifespan

When you choose high bay lights for your warehouse, you should always consider lifespan. The lifespan of your lighting system affects your maintenance schedule, your budget, and your overall productivity. Most high bay lights offer a rated lifespan of 50,000 hours or more. This means you can expect years of reliable performance before you need to replace your fixtures.

You should check the L70 rating when you compare high bay lights. The L70 rating tells you how long the lights will produce at least 70% of their original brightness. A higher L70 rating means your high bay lights will stay bright for a longer period. You can use this information to plan your maintenance and avoid unexpected downtime.

Tip: Choose high bay lights with a long warranty. Many manufacturers offer five-year warranties, which shows confidence in their product’s lifespan.

Here is a simple table to help you understand how lifespan impacts your warehouse lighting costs:

|

Lifespan (Hours) |

Years of Use (12 hrs/day) |

Replacement Frequency |

Maintenance Cost |

|---|---|---|---|

|

30,000 |

~7 |

More often |

Higher |

|

50,000 |

~11 |

Less often |

Lower |

|

100,000 |

~22 |

Rarely |

Lowest |

You should select high bay lights with premium components. Quality LED chips and robust heat sinks help extend the lifespan. Die-cast aluminum housings also improve heat dissipation, which protects the internal parts. You can reduce your maintenance costs and avoid frequent replacements by investing in durable high bay lights.

You should also think about the value for money. High bay lights with longer lifespans may cost more upfront, but they save you money over time. You spend less on replacements and repairs. You also avoid disruptions to your warehouse operations.

When you plan your lighting upgrade, you should ask these questions:

- How many hours per day will your high bay lights operate?

- What is the rated lifespan of the fixtures you are considering?

- Does the manufacturer offer a warranty that matches the lifespan?

- Are the high bay lights built with quality materials for heat management?

You can use these questions to compare products and make a smart decision. Long-lasting high bay lights help you create a reliable lighting system for your warehouse. You support safety, efficiency, and long-term savings.

Note: Always check the technical specifications before you buy high bay lights. A longer lifespan means fewer headaches and better value for your business.

Installation and Maintenance

Installation Ease

You want your lighting upgrade to be as smooth as possible. Many high bay lights come with user-friendly mounting options. You can choose from hook mounts, pendant mounts, or surface mounts. Each method suits different ceiling types and heights. Manufacturers often include clear instructions and all necessary hardware in the box. This approach saves you time and reduces installation errors.

If you have existing wiring, you can often retrofit new high bay lights without major changes. Quick-connect wiring systems make the process faster. Some models even support plug-and-play installation. You can finish the job with basic tools and minimal disruption to your warehouse operations.

Tip: Always turn off the power before you start installing any lighting fixture. Safety should be your top priority.

Maintenance

You want to keep your lighting system running at peak performance. High bay lights require less maintenance than traditional fixtures. LED technology produces less heat and lasts longer. You spend less time and money on replacements.

To maintain your high bay lights, follow a simple routine:

- Inspect fixtures every few months for dust or debris.

- Clean lenses and housings with a soft cloth.

- Check for loose connections or signs of wear.

- Replace any damaged parts right away.

A regular maintenance schedule helps you spot problems early. You avoid unexpected outages and keep your warehouse safe. Many high bay lights come with long warranties, which adds peace of mind.

Upgrade Potential

You should think about the future when you choose your lighting system. High bay lights with modular designs make upgrades easy. You can add smart controls, sensors, or even change the color temperature as your needs evolve. Some fixtures allow you to swap out LED drivers or lenses without replacing the whole unit.

If your warehouse expands or your workflow changes, you can adjust your lighting setup. Look for high bay lights that support wireless controls or integration with building management systems. This flexibility helps you stay efficient and ready for new challenges.

Note: Investing in upgradeable lighting now saves you money and effort later. You can adapt to new technology without a complete overhaul.

Temporary Lighting

You may face situations in your warehouse where permanent lighting does not meet your needs. Temporary lighting fills these gaps. Portable high bay LED lights give you flexibility for maintenance, repairs, or special projects. You can move these lights where you need them most.

When Should You Use Temporary Lighting?

- During equipment maintenance or repairs

- When you set up new storage racks or rearrange layouts

- For construction or renovation projects inside the warehouse

- In emergency situations, such as power outages or safety inspections

- To light up specific work zones for short-term tasks

You do not need to install these lights permanently. You can hang, clamp, or place them on stands. Many portable high bay LED lights come with hooks or magnetic bases. You can attach them to beams, racks, or metal surfaces. This setup saves time and effort.

Tip: Choose portable high bay LED lights with rechargeable batteries for areas without easy access to power outlets. This feature gives you more freedom to work anywhere in your warehouse.

Key Features to Look For

|

Feature |

Why It Matters |

|---|---|

|

High Lumen Output |

Ensures bright, clear light for safe work |

|

Lightweight Design |

Makes it easy to move and set up |

|

Durable Housing |

Withstands drops, dust, and moisture |

|

Adjustable Angles |

Lets you direct light exactly where you need it |

|

Long Battery Life |

Supports long shifts without frequent charging |

|

Quick Setup |

Reduces downtime during urgent tasks |

You should check the IP rating of your temporary lights. A higher IP rating protects against dust and water. This protection is important if you use the lights in damp or dirty areas. You should also look for models with built-in handles or wheels. These features make transport easier.

How to Use Temporary High Bay LED Lights Effectively

- Identify the area that needs extra lighting.

- Choose a portable light with enough brightness for the task.

- Place or hang the light securely to avoid accidents.

- Adjust the angle to reduce shadows and glare.

- Recharge or replace batteries as needed.

Note: Always follow safety guidelines when setting up temporary lighting. Secure cables and stands to prevent tripping hazards.

Temporary high bay LED lights help you maintain productivity and safety during special tasks. You can respond quickly to changing needs in your warehouse. By choosing the right portable lighting, you keep your operations running smoothly, even when challenges arise.

Decision Checklist

Selection Steps

You can simplify your high bay LED lighting decision by following a clear process. Use this checklist to guide your selection:

-

Assess Your Warehouse

Measure ceiling height, layout, and total square footage. Identify task areas and note any special lighting needs. -

Calculate Lighting Requirements

Use a lighting calculation tool. Determine the number of fixtures and the lumen output needed for each area. -

Compare Fixture Features

Check for durability, environmental protection, certifications, and smart controls. Make sure the fixtures match your warehouse conditions. -

Review Energy Efficiency

Look for high lumens per watt and energy-saving features. Consider fixtures with smart controls for extra savings. -

Plan for Installation and Upgrades

Choose fixtures that are easy to install and maintain. Select models that allow for future upgrades or changes. -

Check Warranties and Support

Confirm the warranty period and available customer support. Reliable service helps you avoid future headaches.

Tip: Print this checklist and use it when you compare products or talk to suppliers.

Mistakes to Avoid

You can avoid common pitfalls by staying alert during your selection process. Watch out for these mistakes:

-

Ignoring Ceiling Height

If you choose fixtures with low lumen output for high ceilings, you risk dark spots and poor visibility. -

Overlooking Environmental Ratings

Dusty or damp warehouses need fixtures with proper IP ratings. Skipping this step can lead to early failures. -

Focusing Only on Price

Cheap fixtures may cost less upfront but often have shorter lifespans and higher maintenance costs. -

Neglecting Future Needs

If you do not plan for expansion or upgrades, you may face costly replacements later. -

Skipping Certification Checks

Non-certified lights may not meet safety or efficiency standards. Always look for UL, DLC, or RoHS marks.

Alert: Double-check all technical specs before you buy. Mistakes here can cost you time and money.

ROI Tips

You want your investment to pay off. Use these tips to maximize your return on investment (ROI):

-

Choose High-Efficiency LEDs

Select fixtures with high lumens per watt. You save on energy bills every month. -

Invest in Longevity

Pick lights with a lifespan of 50,000 hours or more. Fewer replacements mean lower long-term costs. -

Leverage Smart Controls

Use occupancy sensors and daylight harvesting. These features cut energy use when full lighting is not needed. -

Apply for Rebates

Many utilities offer rebates for certified LED lighting. Check for local programs to reduce your upfront costs. -

Track Your Savings

Monitor energy use and maintenance costs. Use this data to show the value of your lighting upgrade.

|

ROI Factor |

How It Helps You Save |

|---|---|

|

High Efficiency |

Lowers monthly energy bills |

|

Long Lifespan |

Reduces replacement expenses |

|

Smart Controls |

Cuts unnecessary usage |

|

Rebates |

Lowers initial investment |

Note: A well-planned lighting upgrade pays for itself over time. You boost safety, save money, and prepare your warehouse for the future.

Future-Proofing

Technology Trends

You need to stay ahead of the curve when you upgrade your warehouse lighting. The latest technology trends in high bay LED lighting can help you achieve better efficiency and control. In 2025, you will see several important developments:

- Energy efficiency remains a top priority. Modern lighting solutions can save you up to 80% on energy costs compared to older systems.

- Smart lighting integration is becoming standard. You can use IoT-enabled automation, sensors, and Bluetooth features for advanced control and predictive maintenance.

- The market is growing rapidly, especially in regions like Asia-Pacific, due to industrialization and urbanization.

- Regulatory changes in North America and Europe push for green building standards and higher energy efficiency.

- Smart controls, such as motion sensors and dimming, help you save even more energy and boost productivity.

- Digital transformation and sustainability initiatives will drive strong growth in the LED high bay lighting market from 2026 onward.

You should look for lighting solutions that support these trends. Smart controls and automation give you flexibility and help you manage your warehouse more efficiently.

Expansion

Your warehouse may grow or change over time. You need lighting solutions that can adapt to new layouts, higher ceilings, or additional work zones. Modular fixtures make it easy to add or move lights as your needs evolve. Choose systems that allow you to integrate new technology without replacing your entire setup.

When you plan for expansion, consider these steps:

- Map out possible future changes in your warehouse.

- Select lighting solutions with scalable designs.

- Ensure your system supports easy upgrades, such as adding sensors or smart controls.

This approach saves you money and reduces downtime during upgrades. You keep your warehouse well-lit and ready for any challenge.

Sustainability

Sustainability is more important than ever. You can reduce your carbon footprint by choosing energy-efficient lighting solutions. Many governments offer incentives for businesses that adopt green practices. Regulatory frameworks now encourage carbon reduction and energy savings.

You should select led lighting solutions that meet strict energy standards. Look for products with certifications that prove their efficiency and safety. By using lighting solutions designed for sustainability, you support both your business and the environment.

🌱 Tip: Track your energy use and maintenance costs. This data helps you measure your progress toward sustainability goals and shows the value of your investment.

You now have a clear process for selecting high bay LED lights. Focus on ceiling height, layout, brightness, and energy efficiency. Use the checklist to compare products and avoid common mistakes. Smart choices lead to lower costs and safer workspaces.

Ready to upgrade? Review product specs, consult lighting professionals, and plan your warehouse lighting for 2025. Take action today to secure long-term value and performance.

FAQ

What is the best way to calculate how many high bay LED lights you need?

You should use a lighting calculation tool. Measure your warehouse’s square footage. Enter ceiling height and desired brightness. The tool will suggest fixture quantity and placement for optimal coverage.

How do you choose the right color temperature for your warehouse?

Select cooler color temperatures (5000K–6500K) for inspection or detailed work. Use neutral white (4000K) for general areas. Warmer tones (3000K) suit break rooms. Adjustable fixtures let you change settings as needed.

Can you install high bay LED lights yourself?

You can install many high bay LED lights with basic tools. Follow the manufacturer’s instructions. Always turn off the power before starting. For complex setups, consult a licensed electrician.

What certifications should you look for in high bay LED lights?

Look for UL Listed, DLC Premium, and RoHS Compliant certifications. These marks show your lights meet safety and energy standards. Certified products often qualify for rebates.

How do smart controls help you save energy?

Smart controls let you adjust brightness, set schedules, and use sensors. You reduce energy use by dimming lights when areas are empty or when sunlight is strong.

Are high bay LED lights suitable for cold or damp environments?

Many high bay LED lights have IP65 or higher ratings. These fixtures resist dust and moisture. You can use them in cold storage, damp warehouses, or outdoor areas.

How often do you need to replace high bay LED lights?

Most high bay LED lights last over 50,000 hours. You may only need to replace them every 10 years if you use them 12 hours daily. Long lifespans reduce maintenance costs.